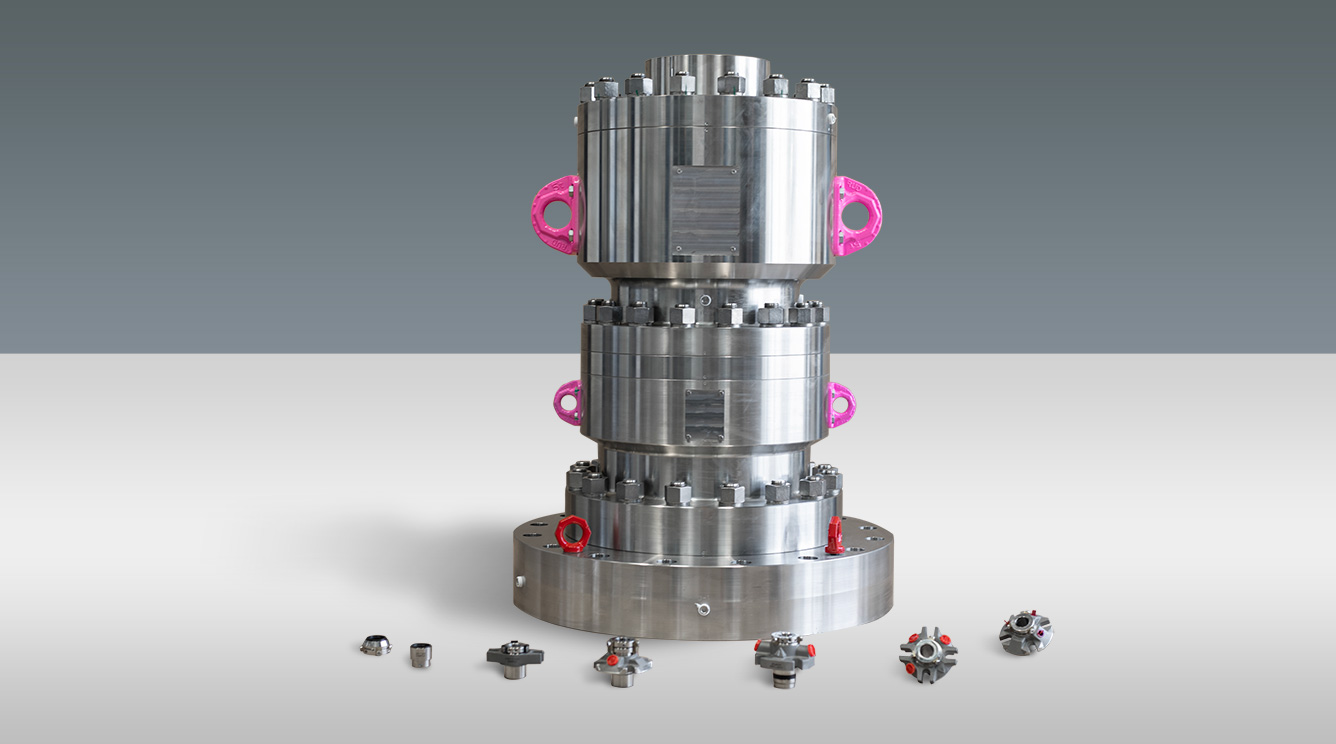

AESSEAL has built one of its largest ever mechanical seals using cutting edge materials and a revolutionary three-section structure.

The cartridge design is bound for the chemical industry on a high-pressure reactor application, comprising a main mounting flange, bearing unit and mechanical seal which can be bench pressure tested prior to installation.

Compared with the competitor component unit it replaces, the 1820 kg assembly can be fitted in hours, and can be easily disassembled and returned in three component parts for expert maintenance off-site.

The seal is rated at a higher working pressure than the 20-year-old design it replaces and is compatible with up-to-date sensor equipment, opening the potential of cloud-based monitoring.

Andrew Parkin, Senior Product Development Engineer said:

Our UK design & manufacturing capabilities allowed us to embark on this project, we enjoyed the challenge of meeting this customer's very specific needs, as well as providing a modern cartridge seal solution with additional benefits compared to the component assembly previously fitted.