Related News For This Country

SW2 brings huge water savings for French brewery

Excessive water consumption was a recurring problem for a brewery in northern France. The OEM sealing solution used a quench to drain seal support system whose water consumption was costing €2,800 per pump.

Reliability the key with DISP seals and FLOWTRUE

Persistent leakage from seals was causing problems for a milk products company in northern France.

AESSEAL braid packing stops persistent product leak

A French aeronautical company was having problems with the leakage of product from the gland packing on a crucial pump.

AESSEAL solves reliability problems for paper company

Persistent leaks from gland packing were causing constant interruptions to the production process at a paper company in south-eastern France. The failure of the packing every few weeks was resulting in damage to the shaft of the pump and causing product to leak into the work area.

CDM the key to greater reliability

A French pulp and paper manufacturer was using gland packing on its pulp tank agitators. This required regular replacement of the packing.

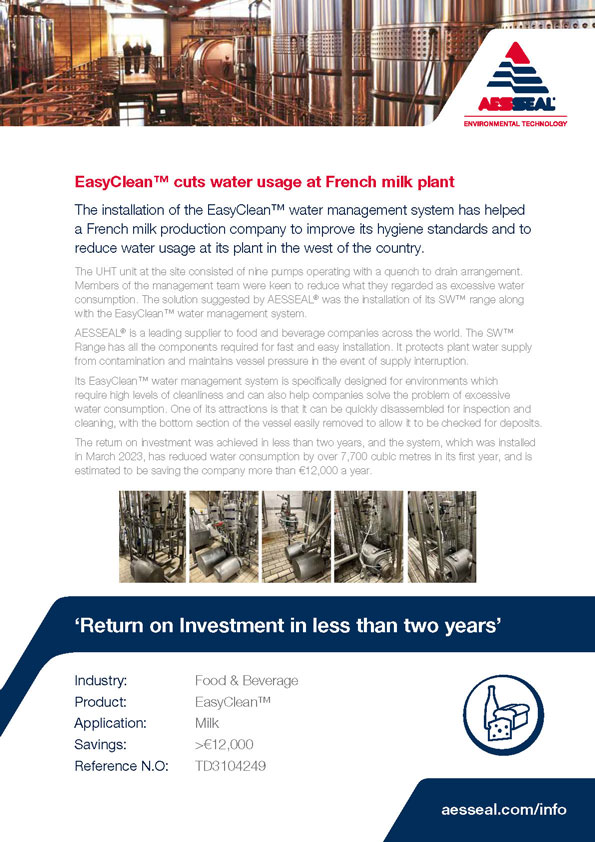

EasyClean cuts water usage at French milk plant

Installation of the EasyClean™ water management system helped French milk production company to improve its hygiene standards and reduce water usage.

DMSC is worth its salt

A poorly-designed seal was causing problems for a major salt producer in eastern France.

AESSEAL improves reliability at French chemical plant

A chemical production company in France was experiencing premature failure of a competitor’s seal on a high temperature terpene process transfer pump.

CDM reliability the answer for seal failures

A corrugated packaging plant in northern France was experiencing persistent seal failures, on average every two months.

EasyClean the answer to excessive water use

Unacceptably high water consumption was a concern for a confectionery company in northern France.

Enhanced production reliability

Failing double component seals were causing problems for a specialist food producer in eastern France.

Chemical plant saved over €500,000 in the first year

A critical glue agitator vessel was affecting productivity for a silicone manufacturing facility in France. This situation was costing the company thousands of Euros in lost production.