Advantages of Double Mechanical Seals

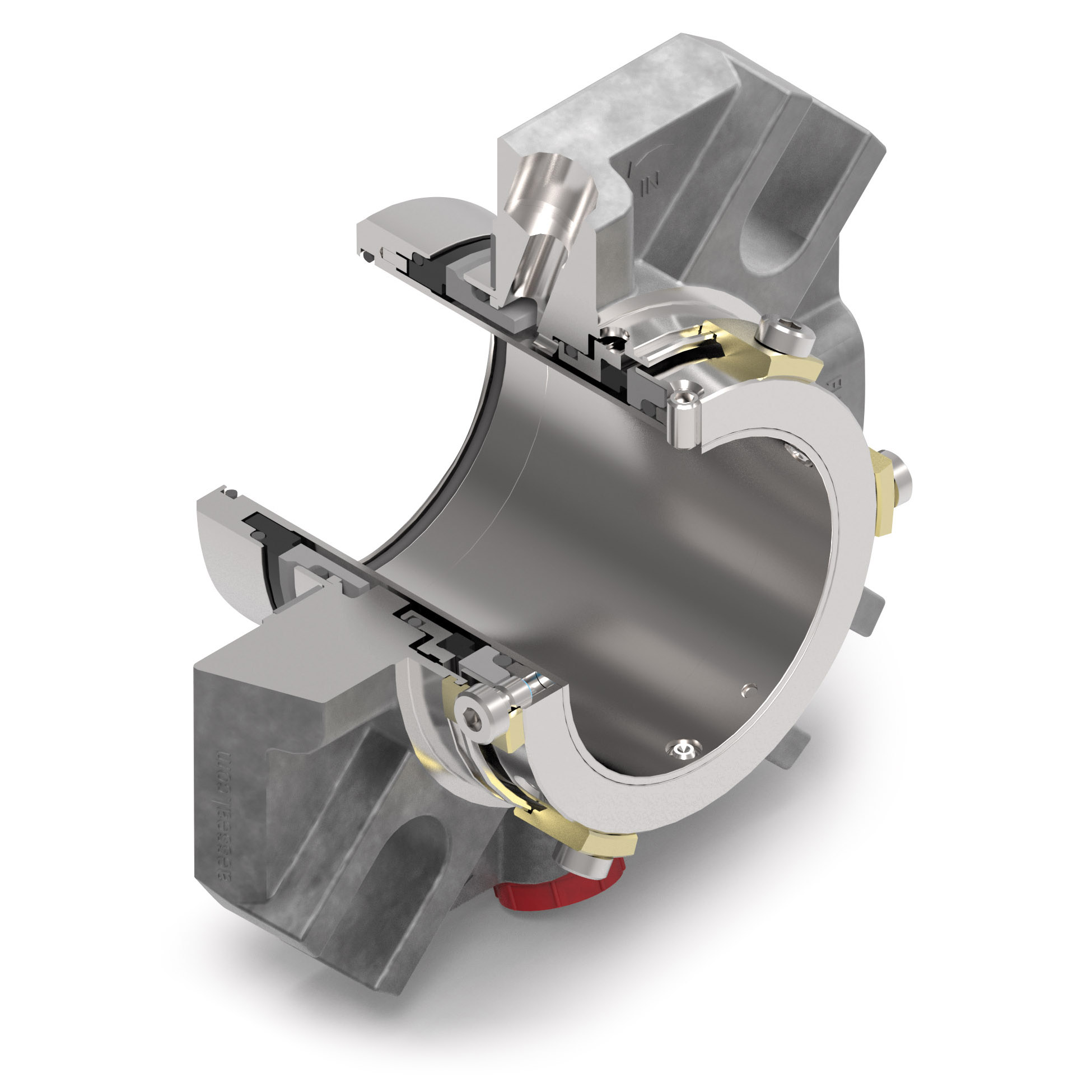

A double or dual mechanical seal consists of two independent seals mounted within a seal chamber outside the pump, which is flushed with an independent supply. This makes them ideal for sealing hazardous liquids, liquids with abrasives or liquids that are corrosive, as the seal faces only see clean lubrication greatly increasing mechanical seal life.

AESSEAL® double mechanical seals have independent seal-face designs, to enhance safe containment of process fluid in the event of damage to any individual sealing element.

AGCD

Double Glandless Cartridge Seal to suit the Sulzer AhlstarUP

CAPI A, B, C Dual

Dual Mechanical Seal – Oil & Gas

CDFI - CDFC

Double Mechanical Seal

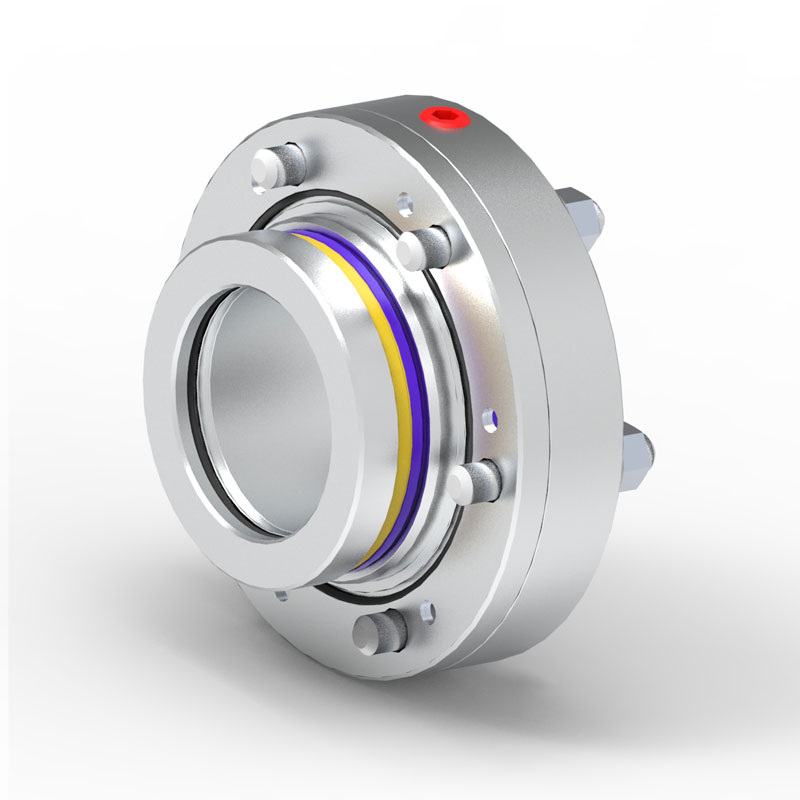

CDP - CDPN

Double Mechanical seal

CDPH Slurry Seal

Medium to Heavy-Duty Double Slurry Seal

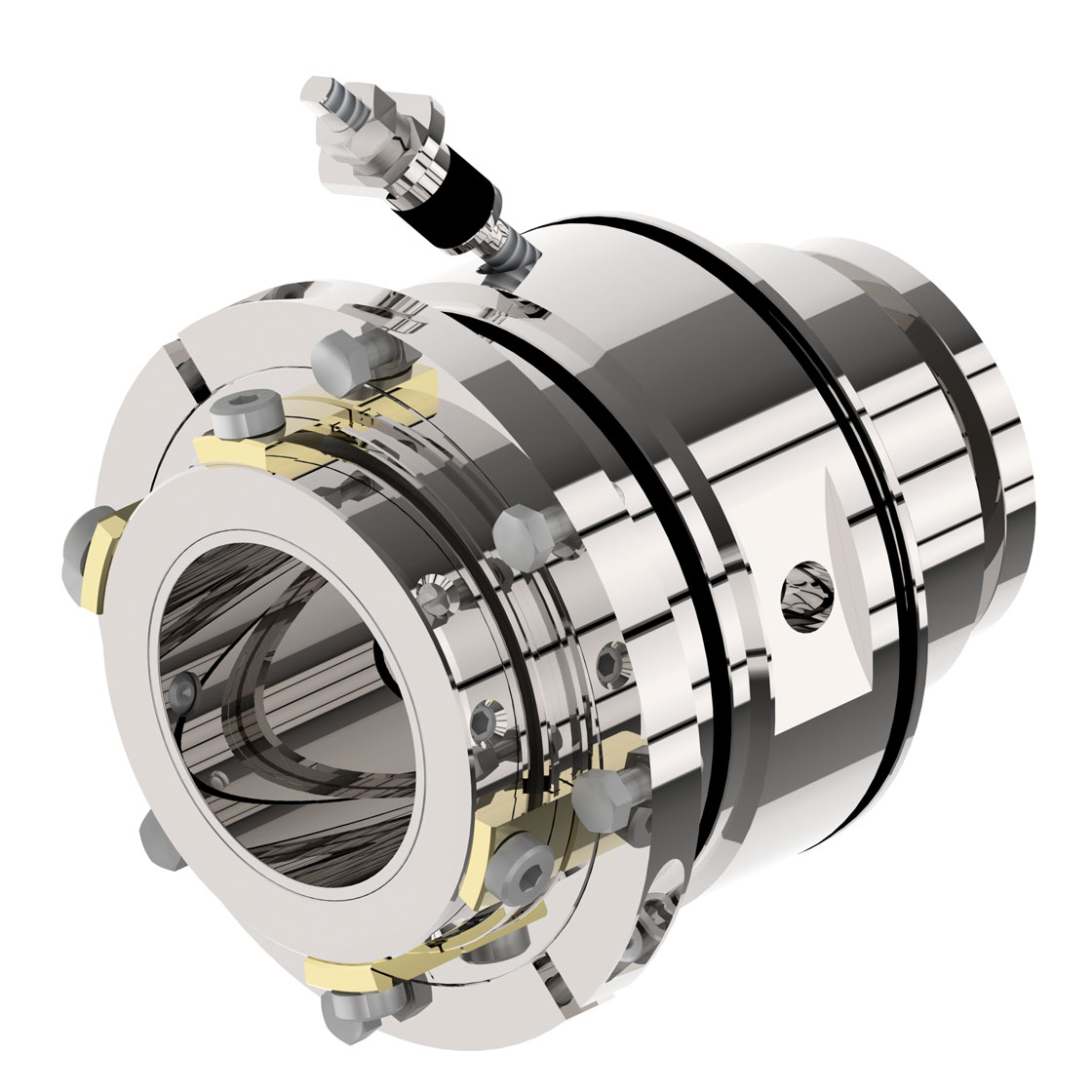

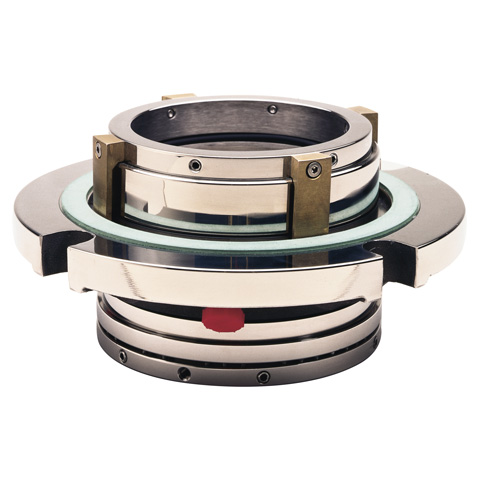

CFFC - HPVD

High Performance Mechanical Seal

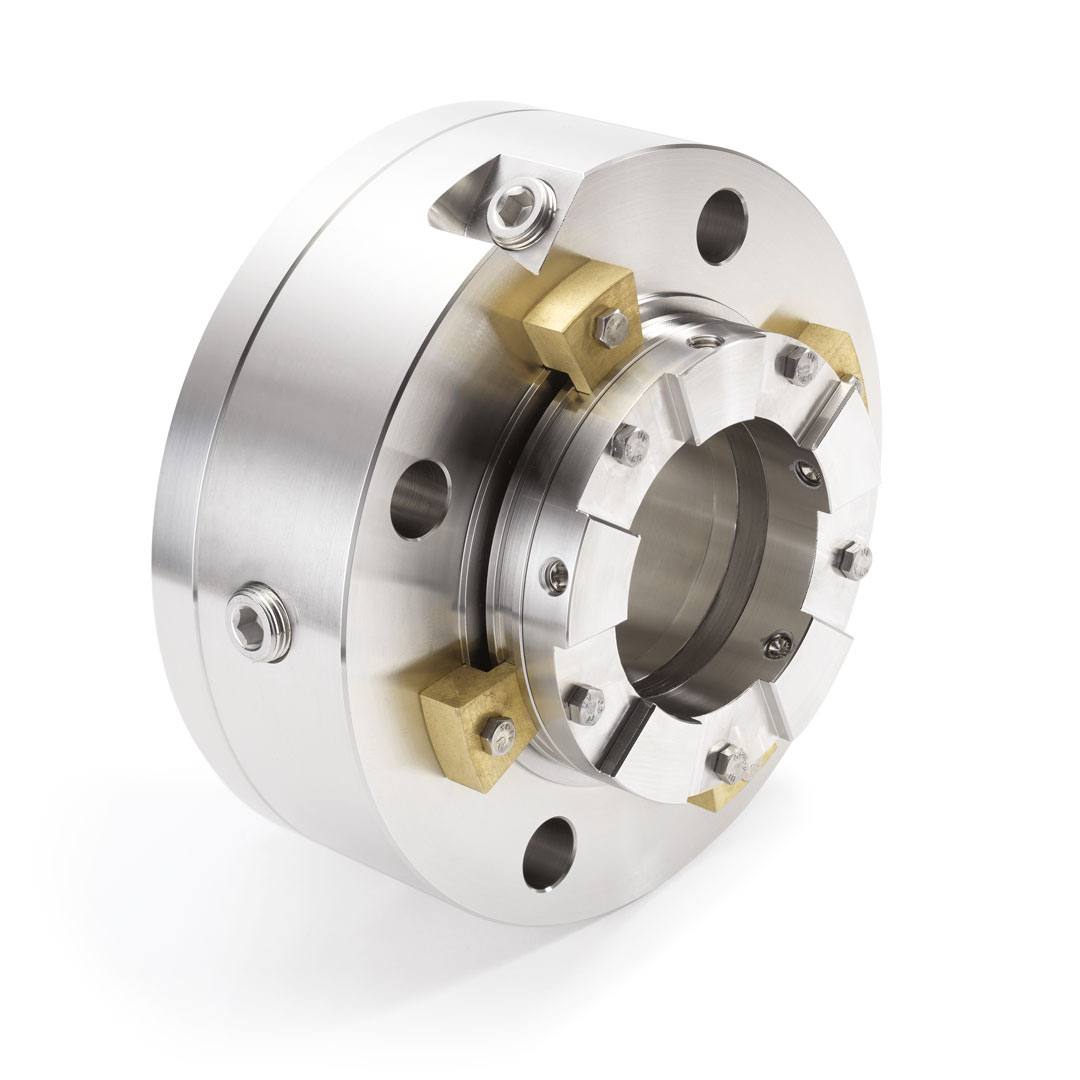

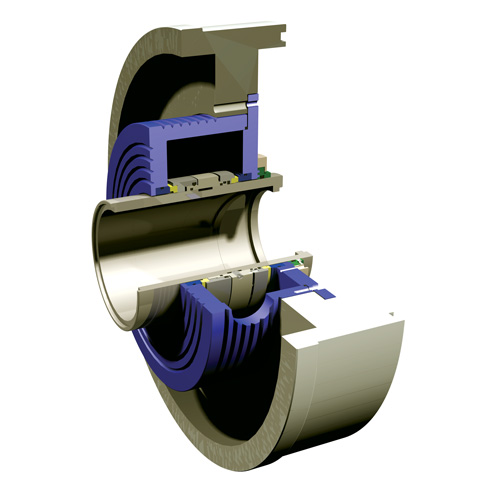

CKD

Double Stationary Seal Range

CKDA

Glandless cartridge double seal to suit Ahlstar UP pumps

The CKSA™ and CKDA™ seals are designed to fit the full six bearing frame range of the AhlstarUP pump models.

D-PCPS

Double Progressive Cavity Pump Seal

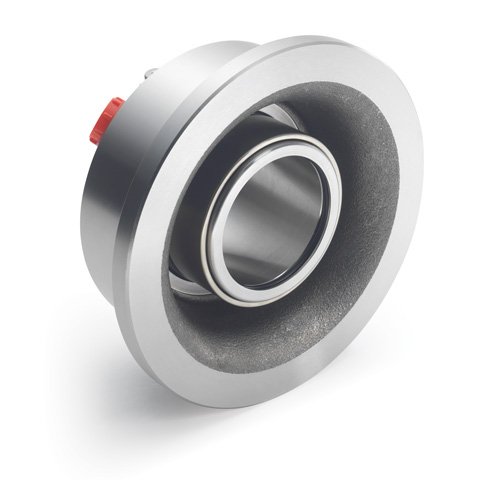

DISP

Double Stationary Seal with Pumping Scroll

DMSF - DMSC

Double Monolithic Stationary Flow / Convection

DSNM - FI-DSNM

Non-Metalic Mechanical Seals

FI-DSNM-R

Richter PCK & SCK Seal

FIDC

Bi-Metal FIDC™ - Flow Induced Dual Cartridge

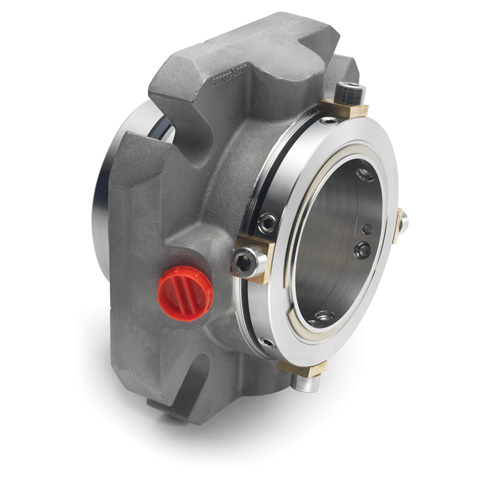

HDSS - HDDSS

Heavy Duty Slurry Seals

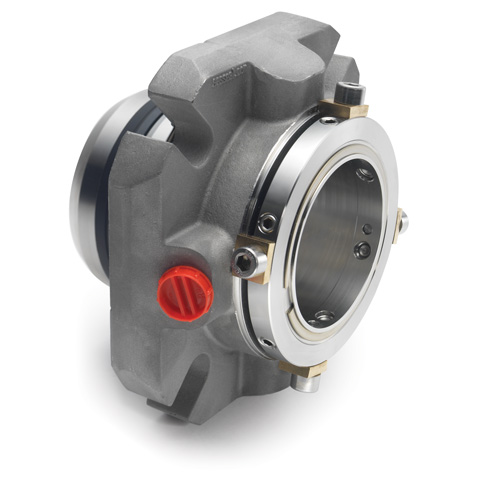

IADC

Pulp & Paper Double Screen Seal

The IADC™ Screen seal design is a double seal available in a wide range of seal face and elastomer applications

LSEAL

L-Series Seal

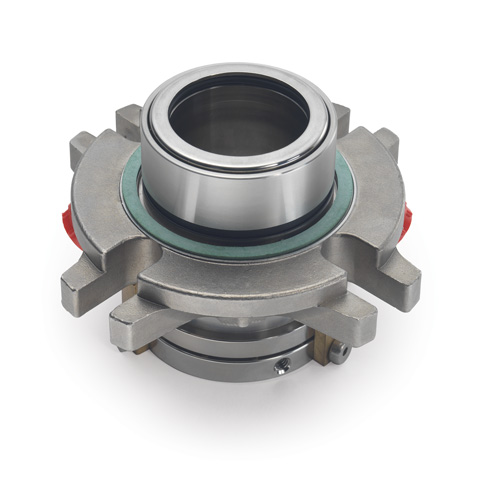

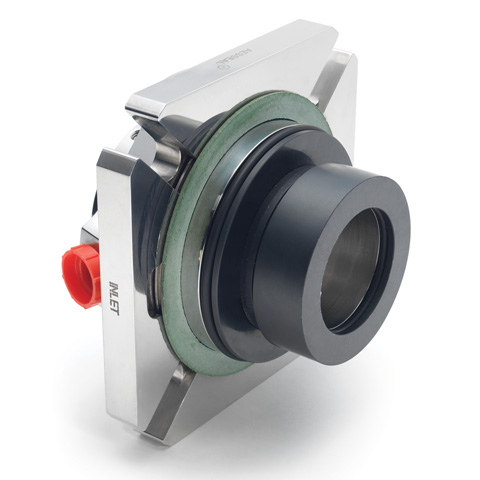

TPDS

Double Heavy Duty Slurry Seal

The TPDS™ double heavy duty slurry seal is designed for use on difficult applications including slurry pumping, tailings, and other heavy-duty slurry seal applications.

UHDDS

Ultra Heavy Duty Double Cartridge Seal