ControlStar FIV

Installation-ready control valve kits

Die Formed Packing

Custom-made ring sets

Scanset

Combination of optimized packing styles and a lantern ring

Set EnviroStar 400-2

Pre-compressed hybrid packing set

Style 210

100% Para-Aramid continuous fiber with PTFE-Blocking Agent

Style 250TP AraStar

Para-Aramid fiber packing with PTFE impregnation

Style 260

Combination braid made of PTFE and Para-Aramid fiber

Style 266TP AllStar

Combination braid of ePTFE Yarn incorporated with Graphite and Meta-Aramid fibers

Style 270

Combination braid of ePTFE with incorporated Graphite

Style 274

Combination braid of ePTFE with incorporated Graphite

Style 275TP SlurryStar

Combination braid of ePTFE with incorporated Graphite

Style 277

ePTFE-Graphite fiber

Style 285TP PaperStar

Meta-Aramid fiber with PTFE-Blocking Agent

Style 288SKE

PTFE fiber packing with mechanical reinforcement

Style 290

Synthetic fiber with PTFE impregnation

Style 295

Combination braid of ePTFE with incorporated Graphite

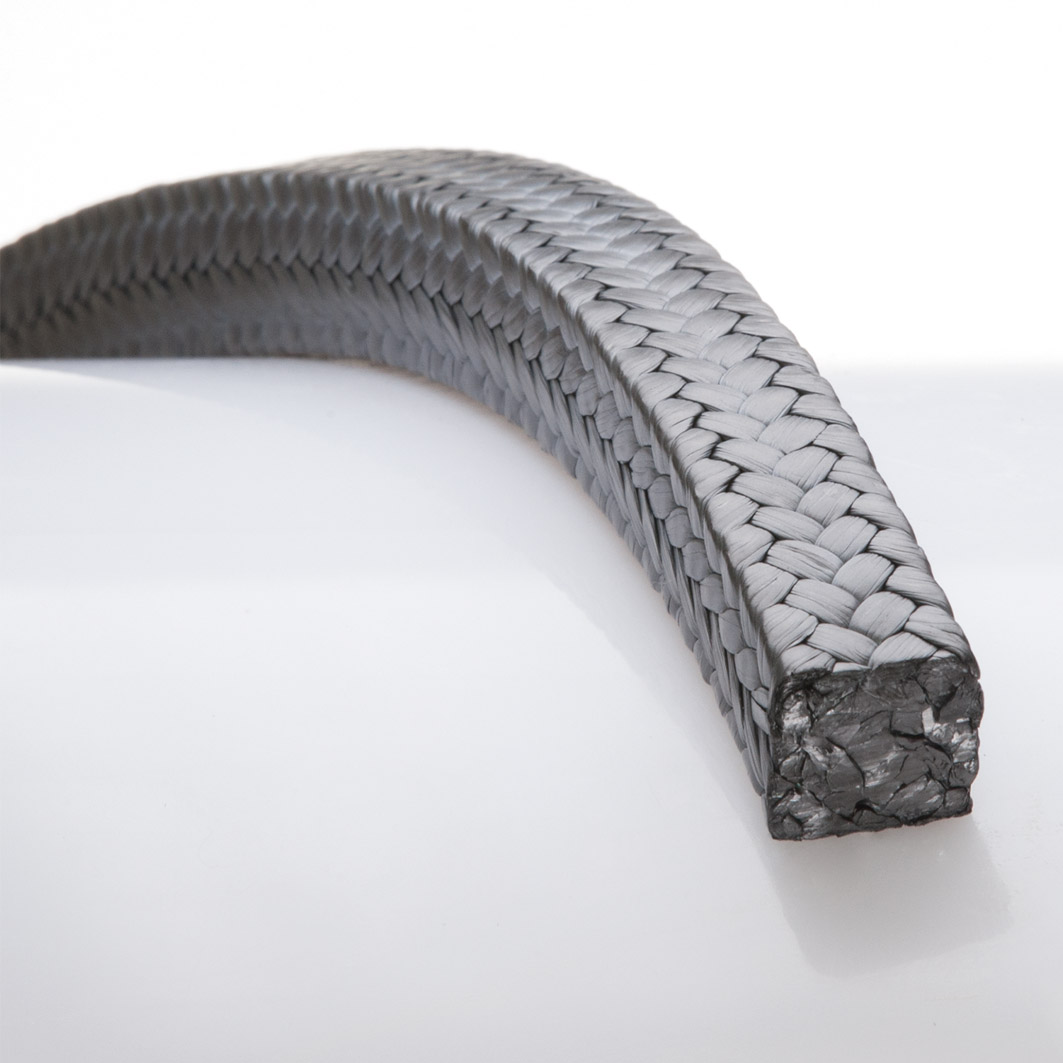

Style 325

Carbon Staple fiber with special Graphite impregnation

Style 326

Synthethic staple fiber

Style 328

Synthethic staple fiber

Style 330

Carbon fiber with special impregnation

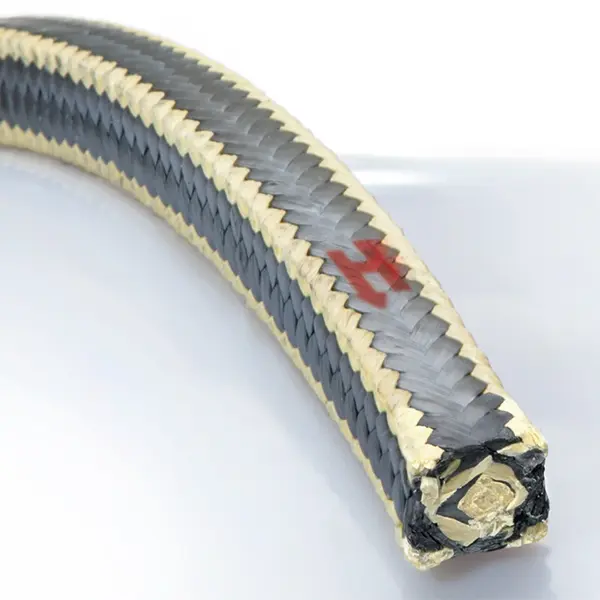

Style 333

Combination braid of Carbon-reinforced expanded Graphite tape and Carbon fiber

Style 337

Braided from Expanded Graphite Tape

Style 340

Braided flexible Expanded Graphite Tape

Style 343

Braided flexible Expanded Graphite Tape

Style 350

Braid made of flexible Expanded Natural Graphite Tape

Style 351

Braided from Expanded Graphite Tape

Style 366TP GraphoStar

Braided from Carbon fiber

Style 380TP CarboStar

High-puricity Carbon fiber

Style 550

Synthetic fiber packing with PTFE impregnation

Style 725SI

100% PTFE fiber with special PTFE dispersion

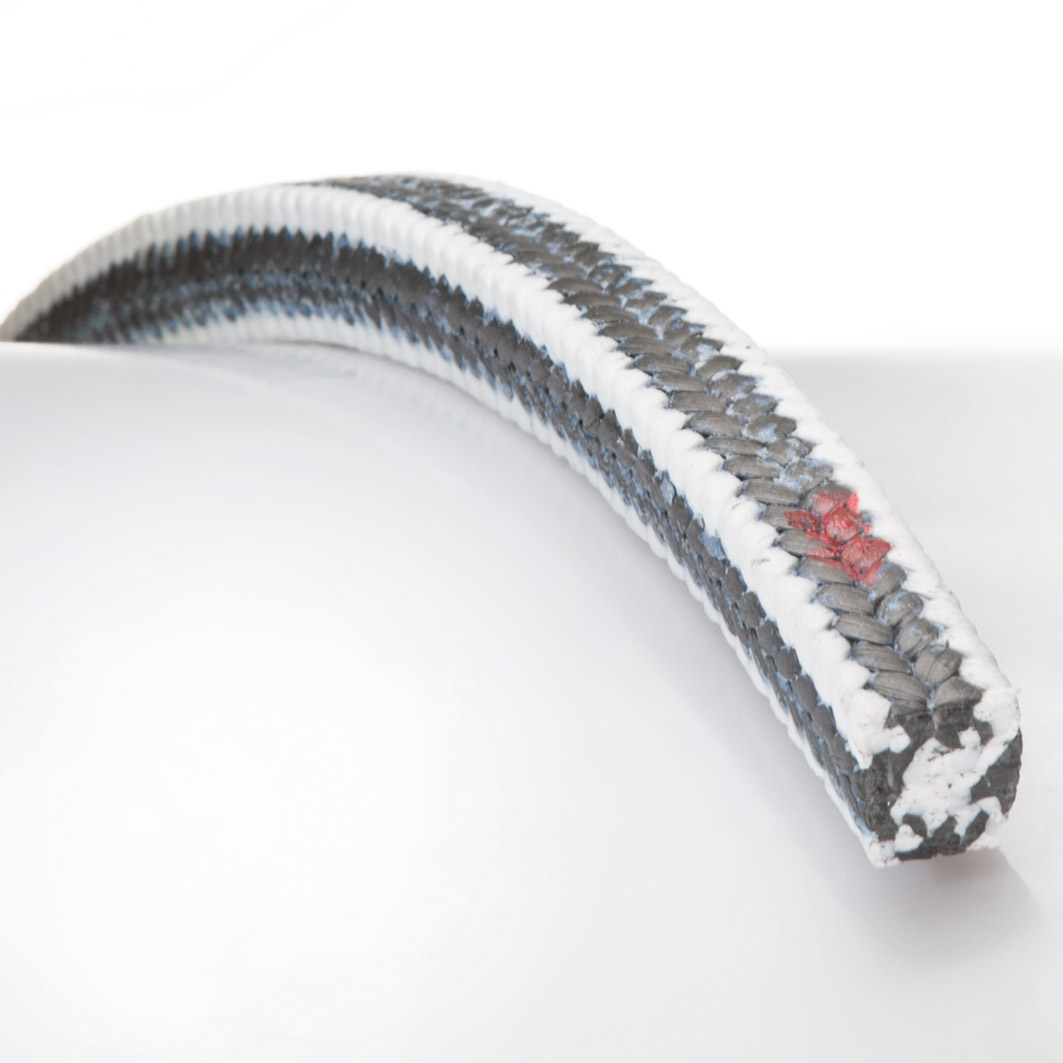

Style 728TP PaperStar HS

Hybrid braid in W-Profile made of heat conductive ePTFE Yarn

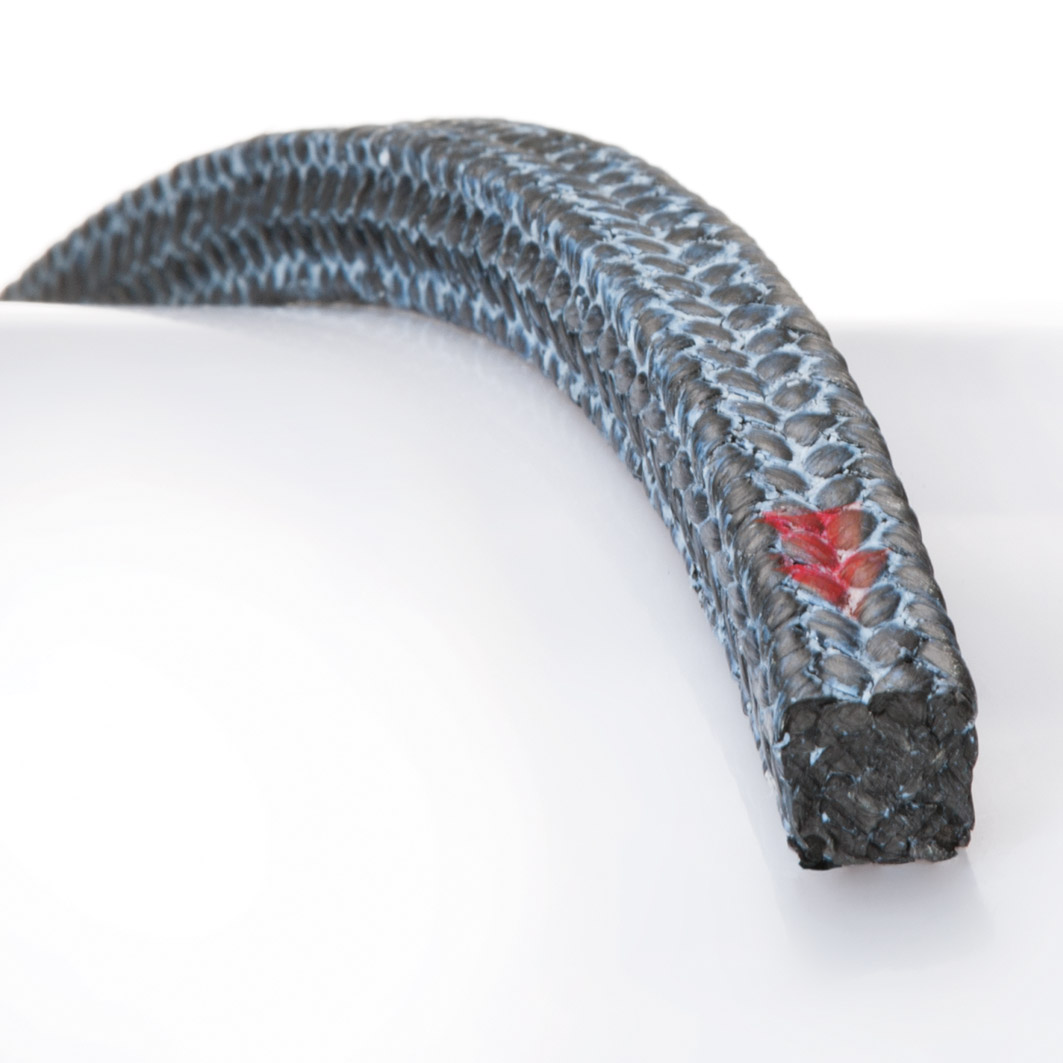

Style 770TP PulpStar

Combination braid of ePTFE with incorporated Graphite

Style 785

Made with 100% GORE® GFO® Fiber: ePTFE

Style 789TP ProStar

Hybrid braid made of ePTFE/Graphite and Carbon/Graphite Yarn

Style 795TP UniStar

Braid of ePTFE Yarn

Style 799

Braid of ePTFE Fiber

Style 840

Para-Aramid fiber packing