Pump packing is used for high shaft speeds. Pump packing contains specially formulated lubricants to aid equipment start up and ensure packing pliability for a longer life.

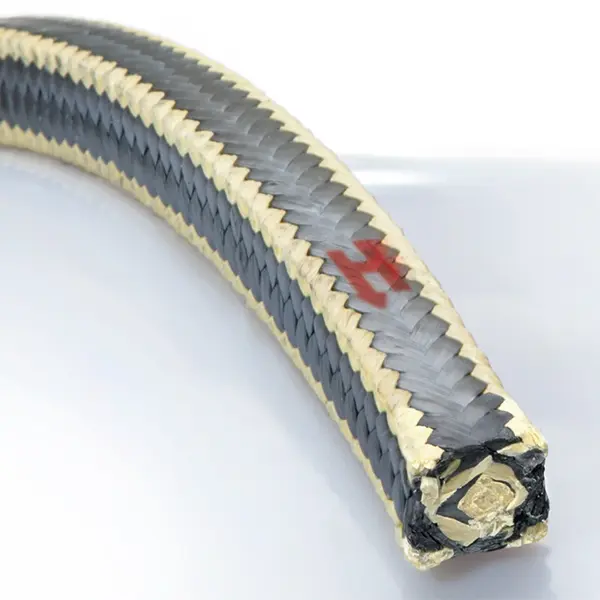

Style 210

100% Para-Aramid continuous fiber with PTFE-Blocking Agent

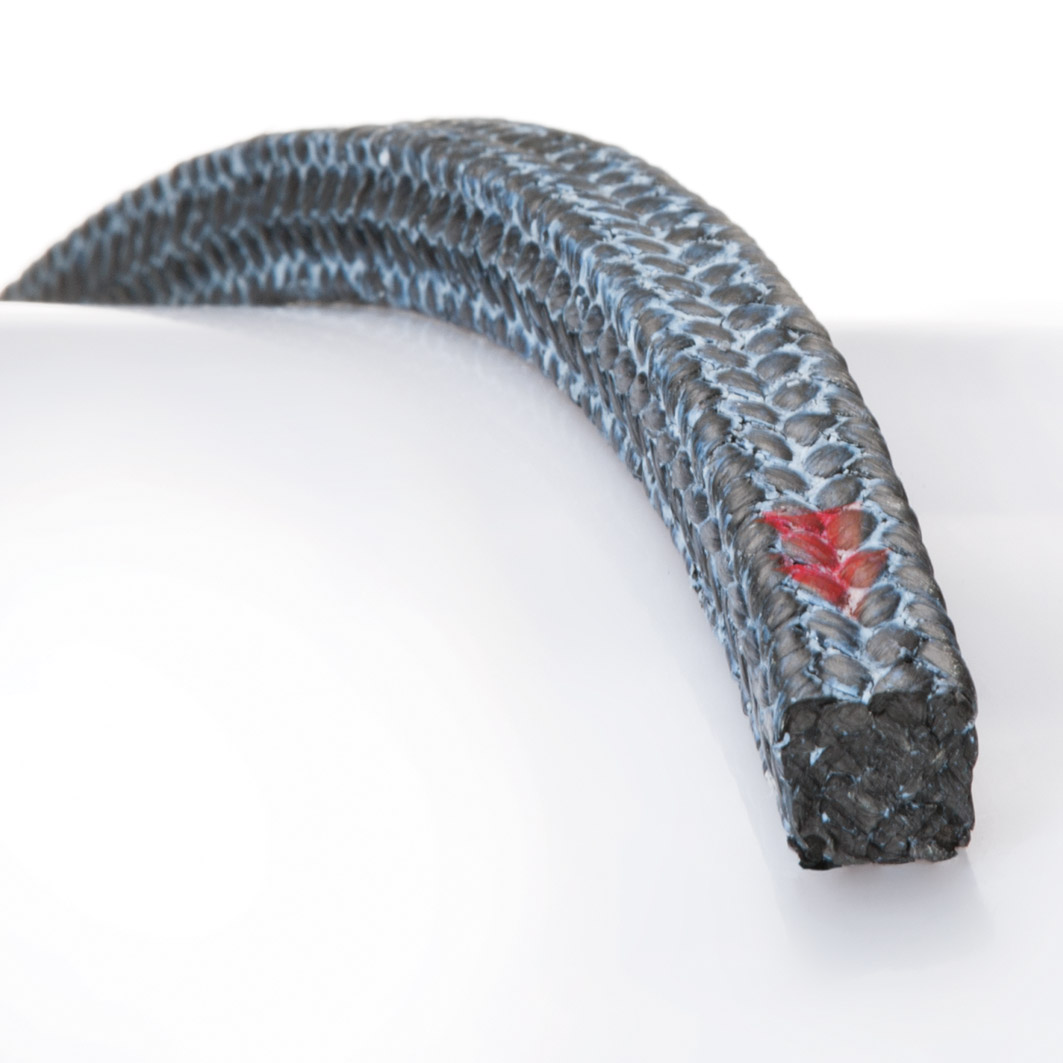

Style 270

Combination braid of ePTFE with incorporated Graphite

Style 274

Combination braid of ePTFE with incorporated Graphite

Style 275TP SlurryStar

Combination braid of ePTFE with incorporated Graphite

Style 277

ePTFE-Graphite fiber

Style 285TP PaperStar

Meta-Aramid fiber with PTFE-Blocking Agent

Style 290

Synthetic fiber with PTFE impregnation

Style 295

Combination braid of ePTFE with incorporated Graphite

Style 325

Carbon Staple fiber with special Graphite impregnation

Style 326

Synthethic staple fiber

Style 328

Synthethic staple fiber

Style 330

Carbon fiber with special impregnation

Style 333

Combination braid of Carbon-reinforced expanded Graphite tape and Carbon fiber

Style 351

Braided from Expanded Graphite Tape

Style 366TP GraphoStar

Braided from Carbon fiber

Style 380TP CarboStar

High-puricity Carbon fiber

Style 728TP PaperStar HS

Hybrid braid in W-Profile made of heat conductive ePTFE Yarn

Style 785

Made with 100% GORE® GFO® Fiber: ePTFE

Style 795TP UniStar

Braid of ePTFE Yarn

Style 840

Para-Aramid fiber packing