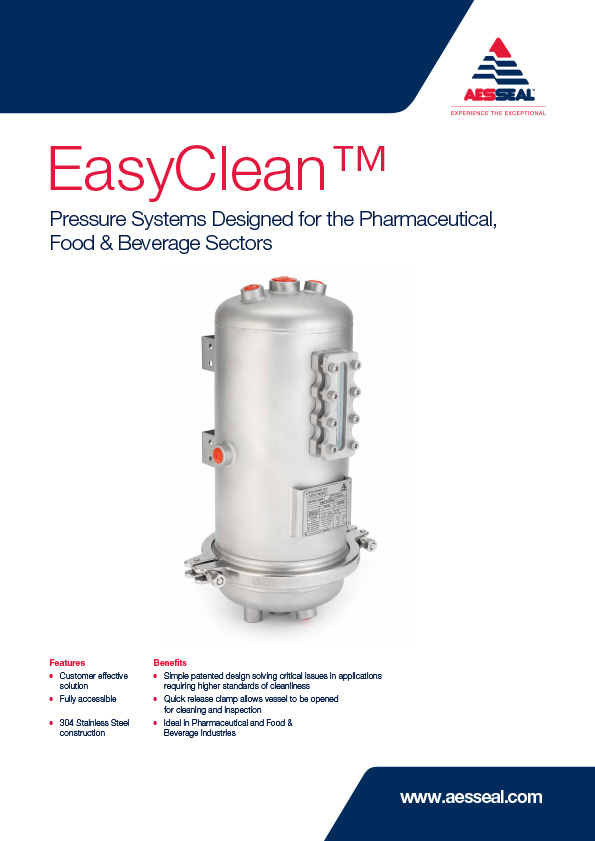

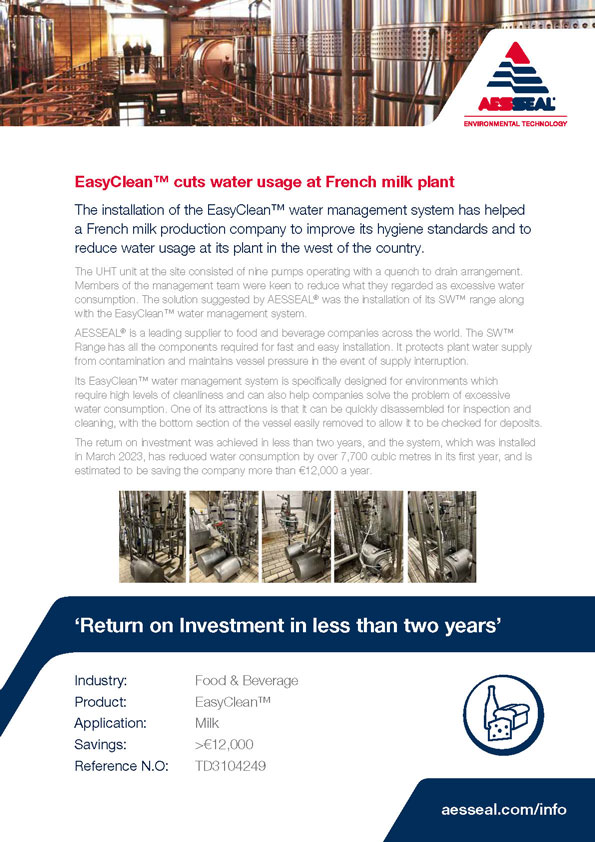

The AESSEAL® EasyClean™ vessel is part of the latest development in water and oil API plan 53a barrier fluid management systems, aimed at environments which require a higher level of hygiene.

In addition to all the features that come with the standard offering of AESSEAL® water and oil management systems the EasyClean™ vessel benefits from the ability to be disassembled for inspection and cleaning.

By using a clamp the bottom section of the vessel can be removed when required and the internal cavity can be checked for deposits. Once the inspection is complete the bottom section is simply reattached using the clamp supplied.

EasyClean™ SW and SP Range

SW or Water Management EasyClean™ Systems are 10L split vessels pressurised by a water supply connection.

SP or Oil Management EasyClean™ systems are 12L split vessels pressurised by a gas supply connection this assembly is also provided with a graduated weld pad to view the fill level.

EasyClean™ vessels are available with a range of options making them suitable for a wide range of applications. Further details can be found within the EasyClean™ brochure.

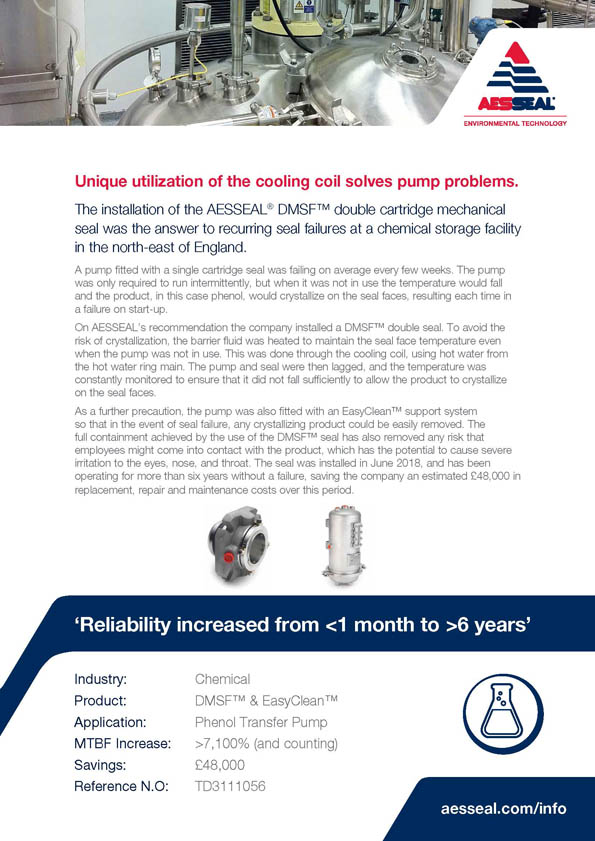

EasyClean™ CC Pressure Systems

In addition to the split design the EasyClean™ CC also includes a cooling coil which can be piped up to a supply source so that the temperature of the barrier fluid can be carefully controlled.

- Integrated cooling coil: Enables the temperature of the vessel to be optimized.

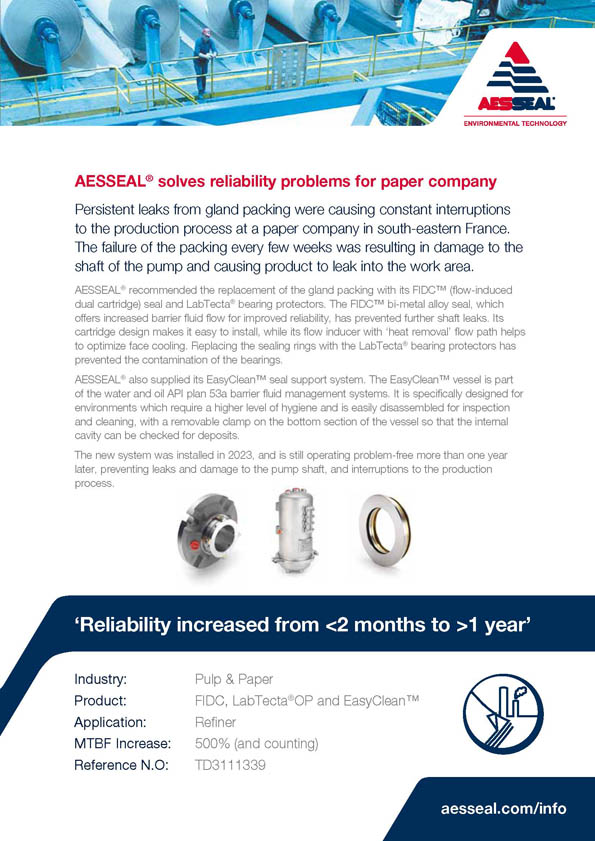

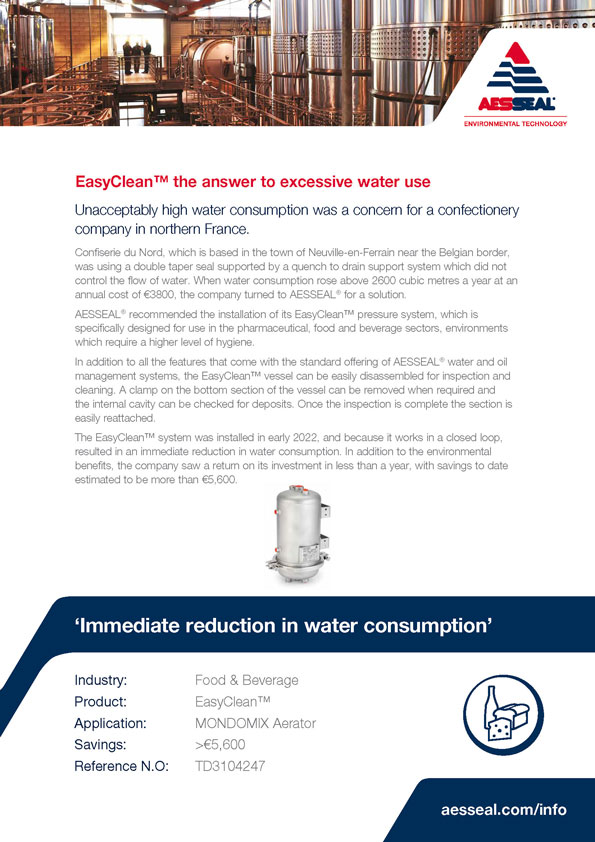

EasyClean™ WP Pressure Systems

The EasyClean™ WP incorporates a Weld Pad Level Gauge which is graduated so as to accurately show the fill level of the vessel.

- Weld pad graduated level gauge: Robust and Industrially acceptable visual indication of fluid level.

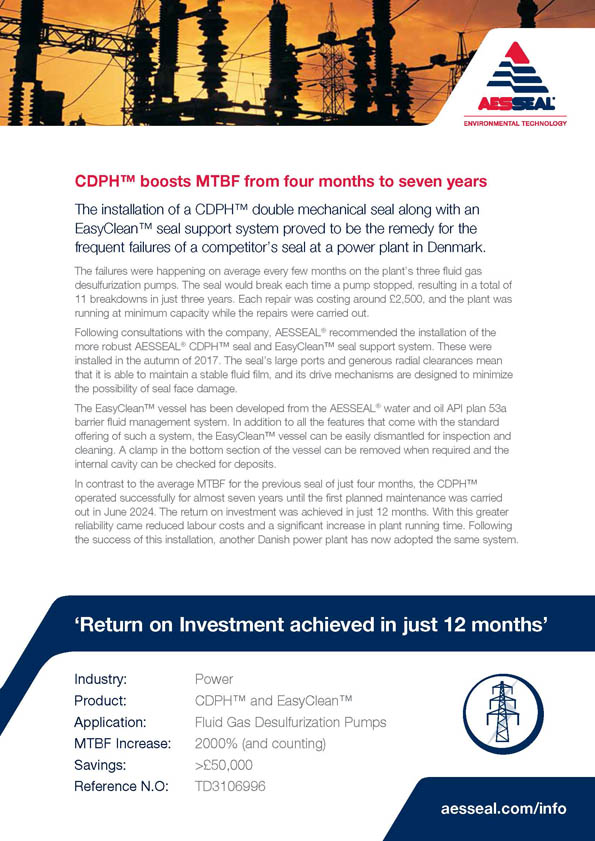

EasyClean™ WPCC Pressure Systems

The EasyClean™ WPCC also includes a cooling coil which can be piped up to a supply source so that the temperature of the barrier fluid can be carefully controlled. In addition to the cooling coil the vessel also incorporates a Weld Pad Level Gauge which is graduated so as to accurately show the fill level of the vessel.

- Weld pad graduated level gauge: Robust and Industrially acceptable visual indication of fluid level.

- Integrated cooling coil: Enables the temperature of the vessel to be optimized.

Suitable for the following API Plans

Suitable for the following industries