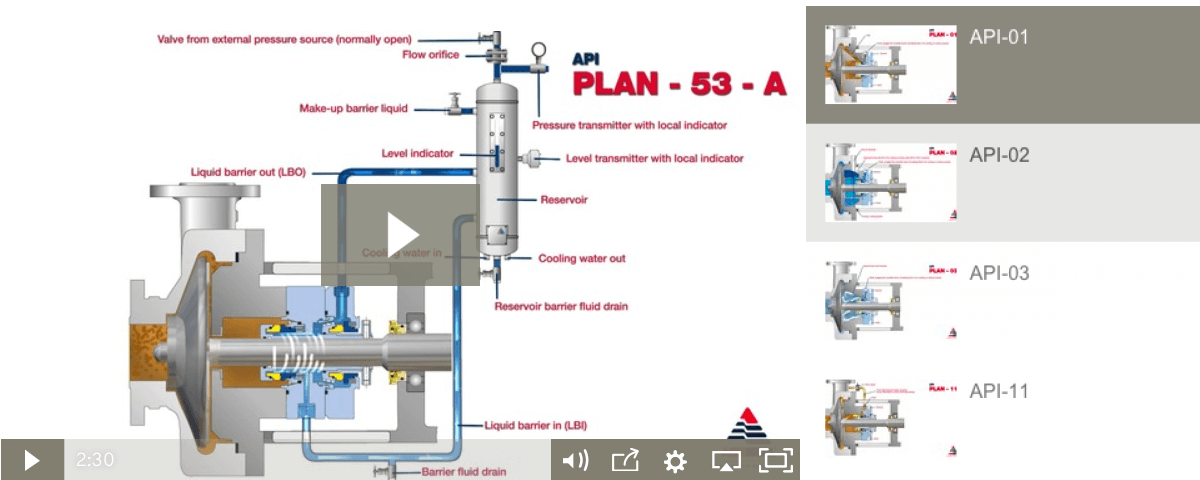

Description

Product recirculation from discharge through flow control orifice and heat exchanger to seal chamber.

Features

- Improves pressure margin over vapour pressure.

- Improves temperature margin to meet secondary sealing element limits, to reduce coking or polymerizing and to improve lubricity.

- Self venting plan.

- Provides sufficient pressure difference to allow proper flow rate.

Use

- For high temperature applications e.g. hot water application (temperature > 80ºC), hot hydrocarbons etc.

- In hot non-polymerizing fluids.

Caution

- Always ensure that cooler is placed after the orifice.

- Check pressure difference between discharge and seal chamber.

- Cooler duty is high leading to fouling on waterside.

- Potential plugging on process side if fluid viscosity rises quickly.