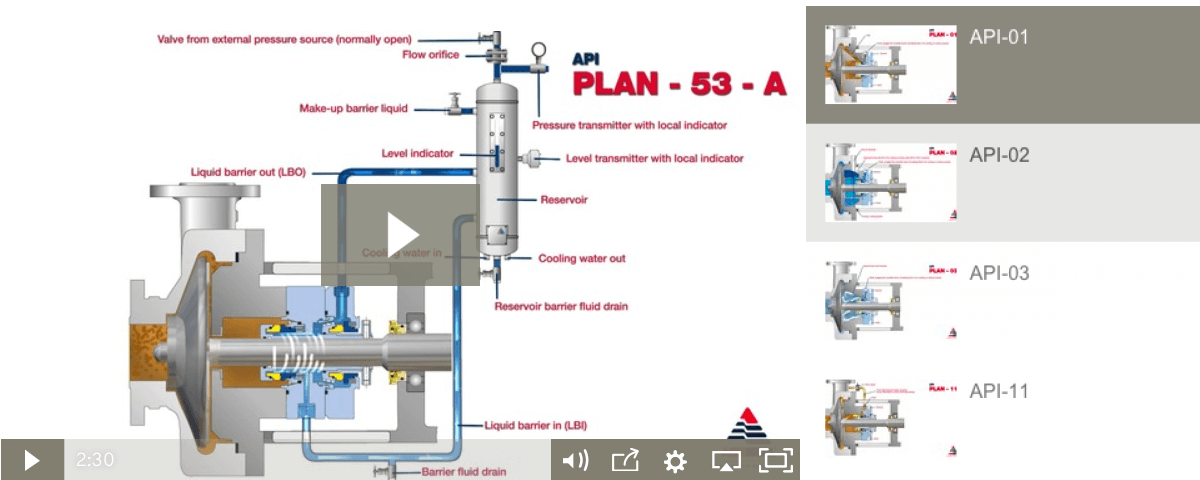

The AESSEAL® Seal Auxiliary Systems Division has established a pioneering method of developing API Plan 53B Systems.

Plan 53B systems have been viewed as an “engineering challenge” around the world, often with long lead times. The innovative modular concept permits 12 modular options to be applied to create an API 53B System for any application. This modular process facilitates efficient stock control which in turn provides AESSEAL® API 53B Systems with rapid delivery times. Modularity eases the production of documentation for each Plan 53B product and also makes it easier to determine the correct solution for the application.

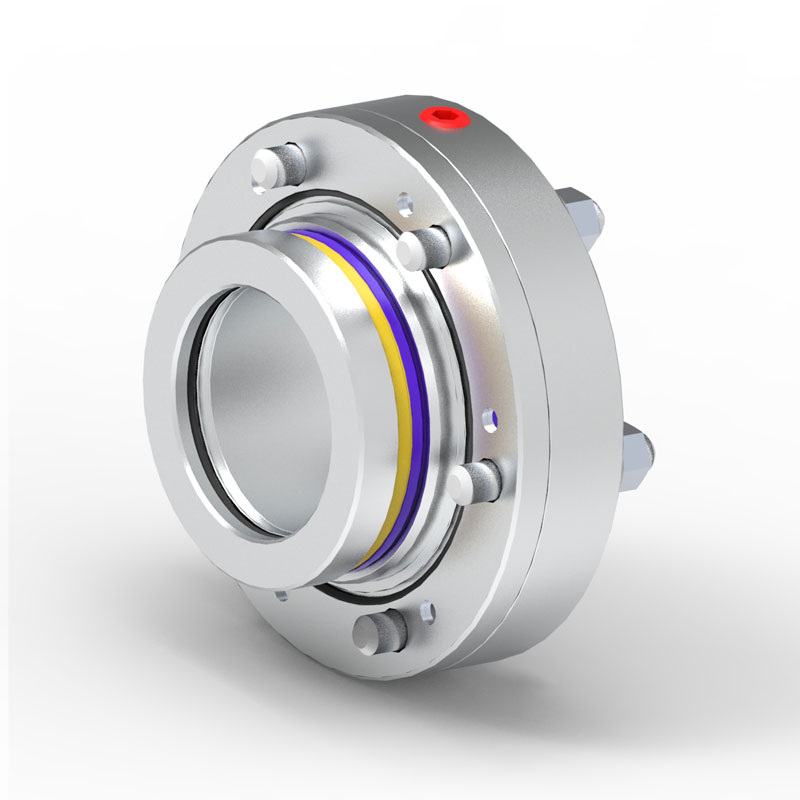

Description

Pressurised barrier fluid circulation in outboard seal of dual seal configuration. Circulation is maintained by using pumping ring in running condition and with thermosyphon effect in stand still condition. The pressure is maintained in the seal circuit by a bladder accumulator.

Features

- Keeps barrier fluid and pressurised gas (inert gas) separate by using a bladder.

- Heat is removed from the circulation system by an air-cooled or water-cooled heat exchanger.

- Being a stand-alone system does not rely upon a central pressure source. Hence much more reliable than a Plan 53A.

- In no case will media leak to atmosphere.

- Clean fluid film formation between the inboard seal faces gives better seal life.

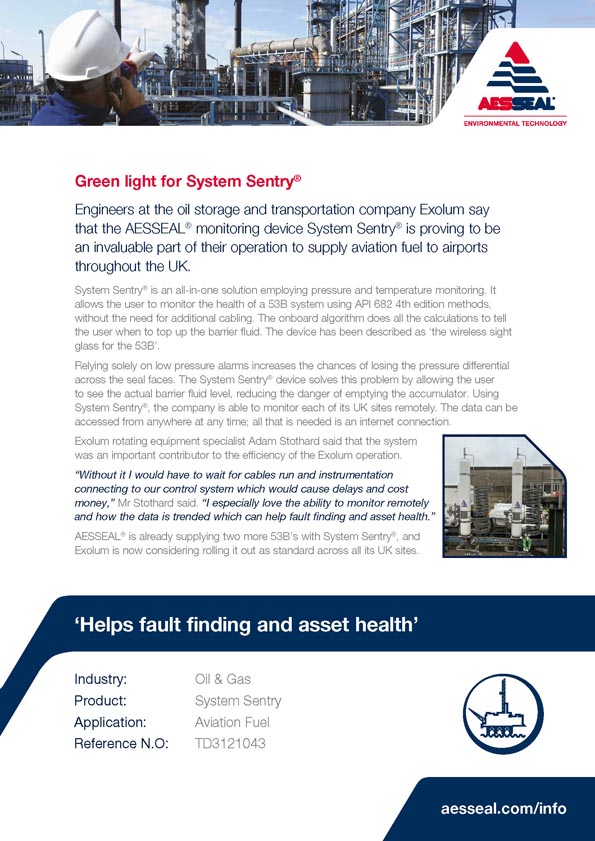

Use

- Applications where no leakage to atmosphere can be tolerated e.g. hazardous, toxic, inflammable media.

- For dirty, abrasive or polymerizing products where media is unsuitable as a lubricant for inboard seal faces.

Caution

- There will always be some leakage of barrier fluid into the product. Check compatibility of barrier fluid with product.

- Low volume of barrier fluid in system, hence heat dissipation is totally dependent on cooler efficiency.

- Always recharge bladder to 0.9 times the working pressure.

- Vent the system properly before start up.

- Product quality can deteriorate due to barrier fluid contamination.