A US corn processing company has saved thousands of dollars in less than a year following the installation of an AESSEAL DMSF double cartridge mechanical seal.

Biofuels Case Studies

AESSEAL upgrade removes safety risk

A sealant being used on an Sulzer APP3 pump by a Spanish biofuel company was leaking each time the pump was stopped.

Improved reliability using dual seal and system

A corn wet milling plant in the USA had a problem with leaking seals on the centrifugal pumps.

AESSEAL seals the deal

A US oil seed producer was finding that the single seals used in the production process were inadequate, and were failing on average every three to six months.

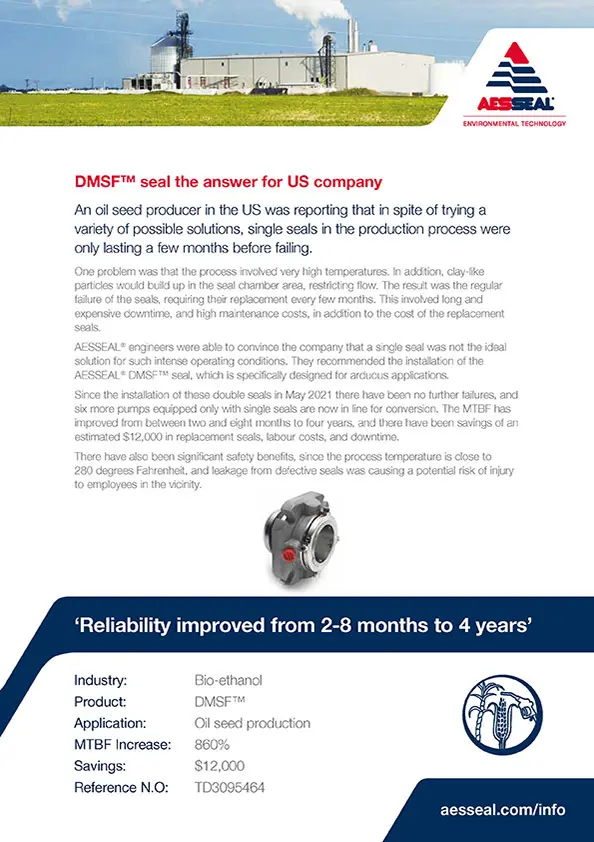

DMSF seal the answer for US company

An oil seed producer in the US was reporting that in spite of trying a variety of possible solutions, single seals in the production process were only lasting a few months before failing.

Significant savings with new AESSEAL system

A corn milling company in the Midwest of the United States is in line to save hundreds of thousands of dollars.

AESSEAL helps significantly reduce downtime

A US corn milling and food additives company was reporting problems resulting from incorrectly cut bulk packing.

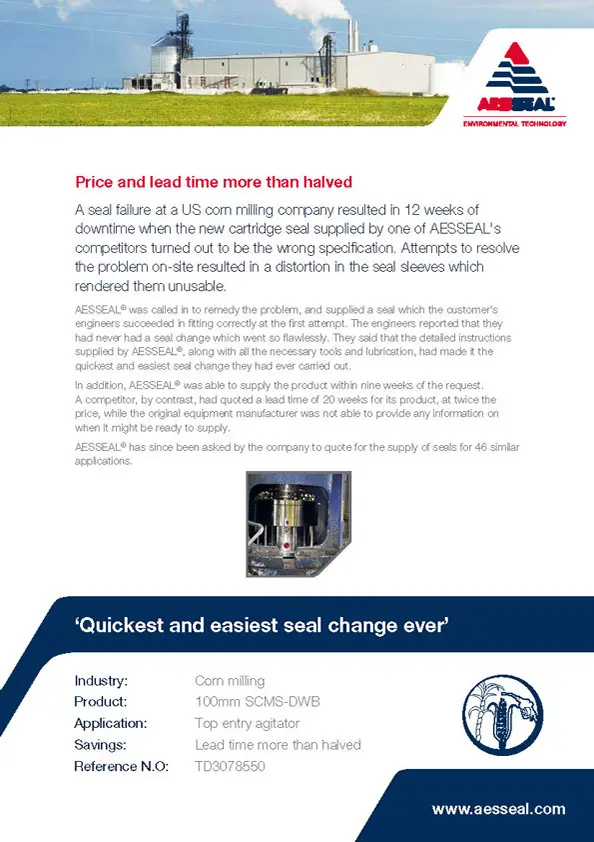

Price and lead time more than halved

A seal failure at a US corn milling company resulted in 12 weeks of downtime when the new cartridge seal supplied by one of AESSEAL’s competitors turned out to be the wrong specification.

Massive water savings with improved reliability

A Bio Products manufacturer was concerned about the water used by the sealing systems at one of its manufacturing facility in the USA.

DMSF improves reliability

A bio-ethanol production plant in Poland was experiencing premature failure of a competitors single seal.

DMSF upgrade saves over £460,000 a year

One of the largest Bioethanol production plants in Europe was having a failure every 2 months on a group of pumps in the distillation area of the plant, costing over £75,000 per outage.