Case Ref

TD3100059

Country

United States

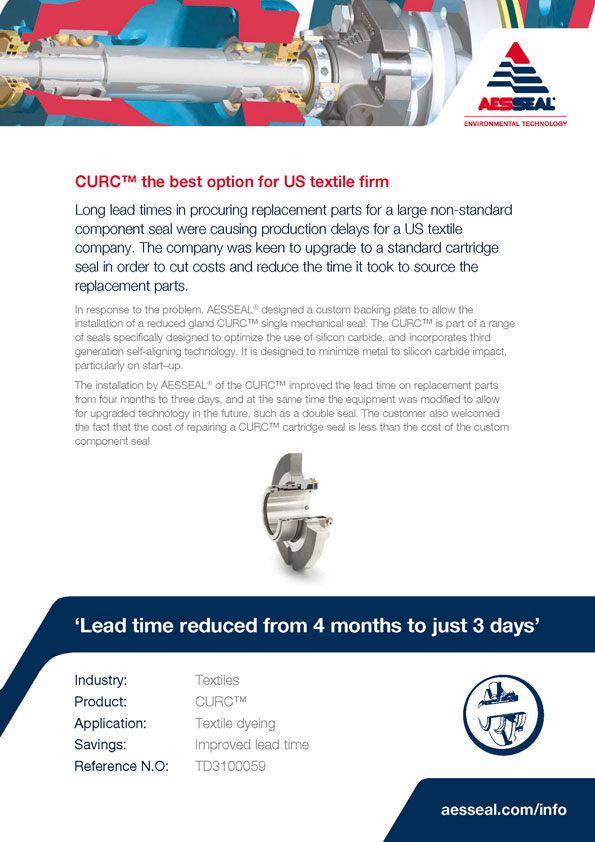

Long lead times in procuring replacement parts for a large non-standard component seal were causing production delays for a US textile company. The company was keen to upgrade to a standard cartridge seal in order to cut costs and reduce the time it took to source the replacement parts.