Case Ref

CS0004

Country

United States

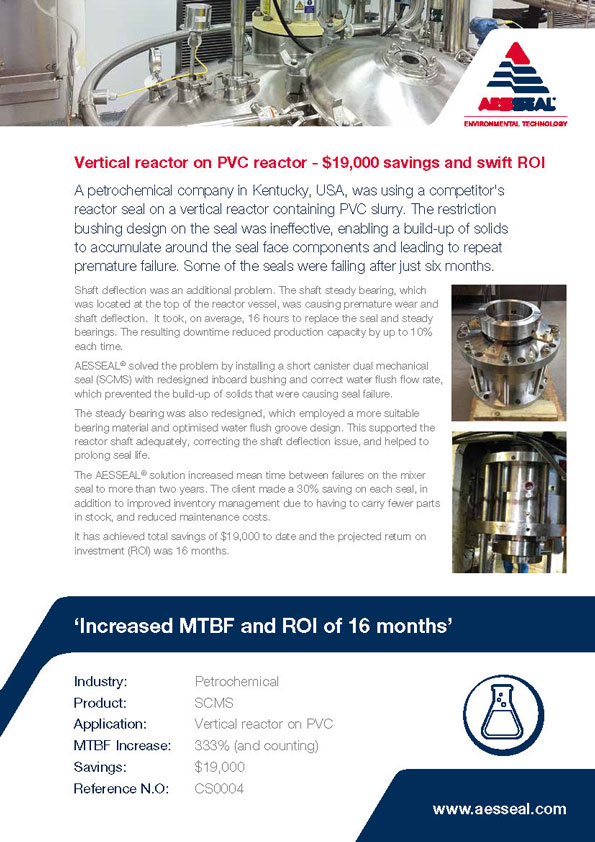

A petrochemical company in Kentucky, USA, was using a competitor’s reactor seal on a vertical reactor containing PVC slurry. The restriction bushing design on the seal was ineffective, enabling a build-up of solids to accumulate around the seal face components and leading to repeat premature failure. Some of the seals were failing after just six months.

More Industry Related Content