Increase your pump bearing life. Watch the 6 minute video

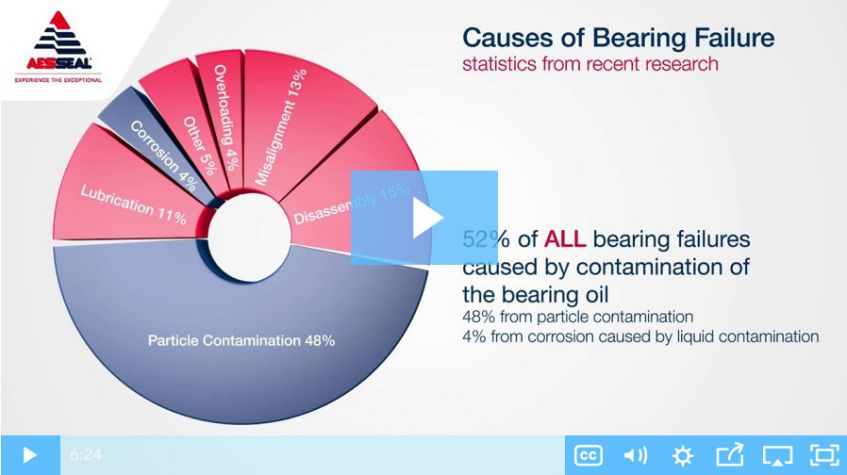

Research shows that 52% of bearing failures are due to contamination of the bearing oil*.

Research into Bearing Failures

Reliability by numbers: 52% of bearing failures. A study into equipment reliability conducted at a major refinery has published statistics on causes of equipment failure. They concluded that 40% of overall rotating equipment failures (pumps mixers etc) were due to bearing failure.

They further estimated that 48% of all bearing failures were due to particle contamination and 4% were due to corrosion (caused by liquid in the oil). Therefore 52% (total contamination cause) of 40% (bearing failures) = 20.8% of all rotating equipment failures are caused by contamination of the bearing oil.

Save your bearings and improve your reliability with our bearing protection range. The upgrade is non-contacting and field-repairable quickly: so it should survive unrelated equipment failures and last for an extremely long time.

* Bloch Heinz; “Pump Users Handbook: Life Extension” 2011.

For more information on the LabTecta range; read our White Paper on LabTecta Life Expectancy

Also for real life examples of how the LabTecta range has benefitted our clients view the LabTecta Case Histories pack.