Recommended Products in this Industry

With a documented 99.4% start-up success rate at the height of the ethanol build period in North America positioned AESSEAL® as a market leader in the ethanol industry. AESSEAL® modular seals and seal support systems have been proven to deliver improved reliability and reduce costs.

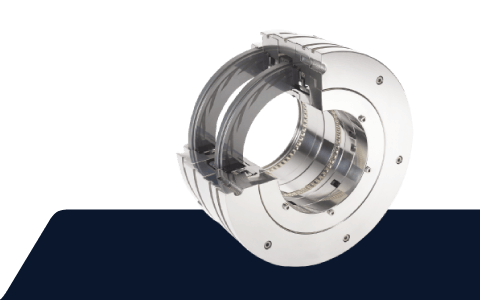

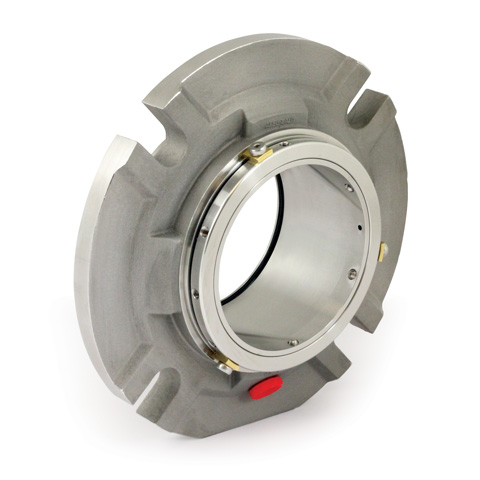

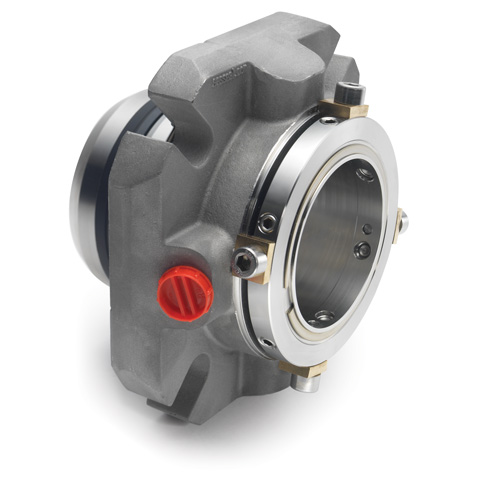

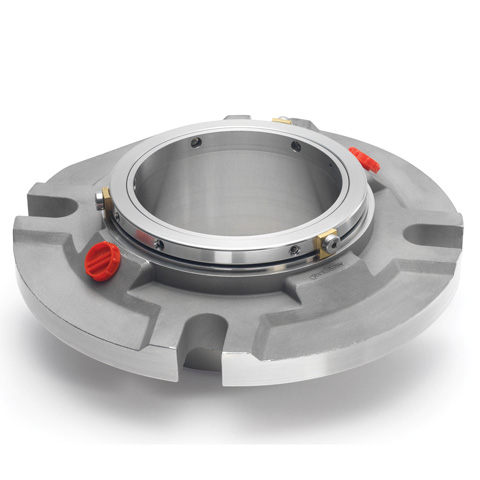

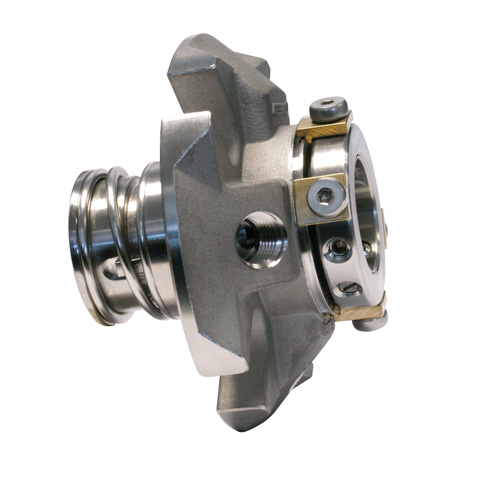

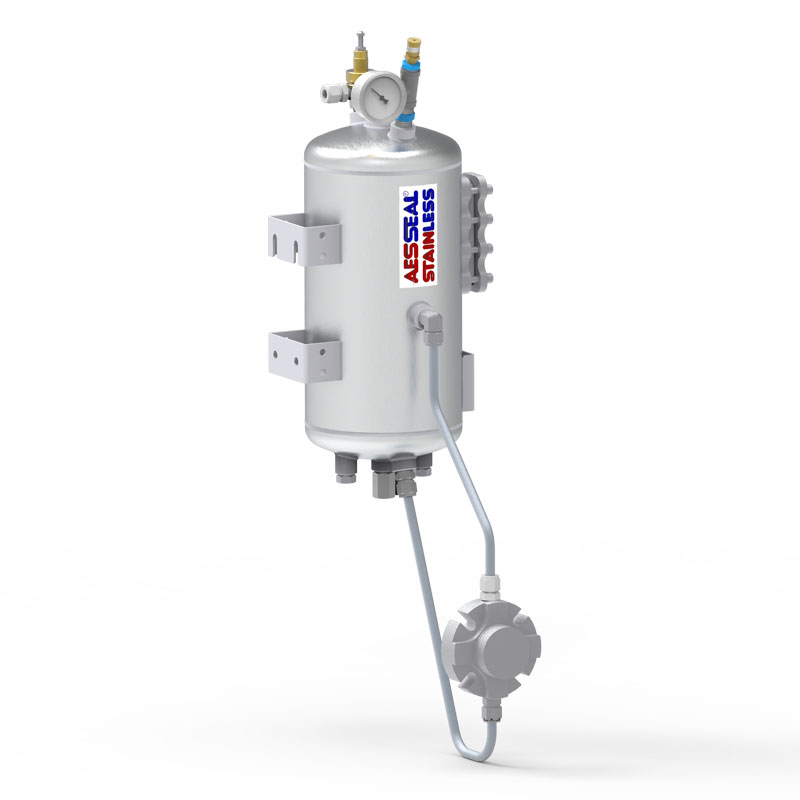

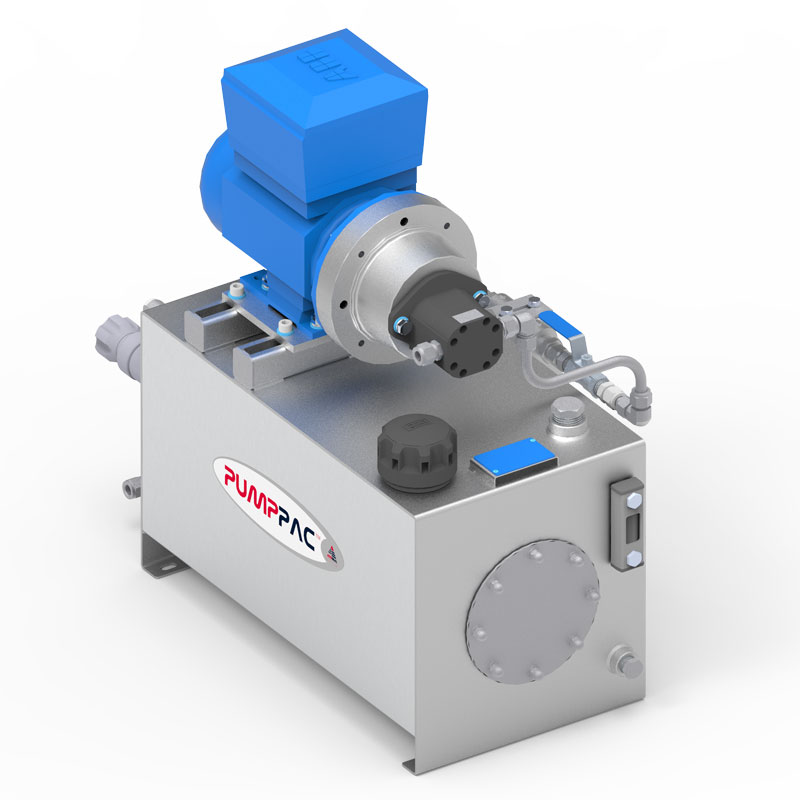

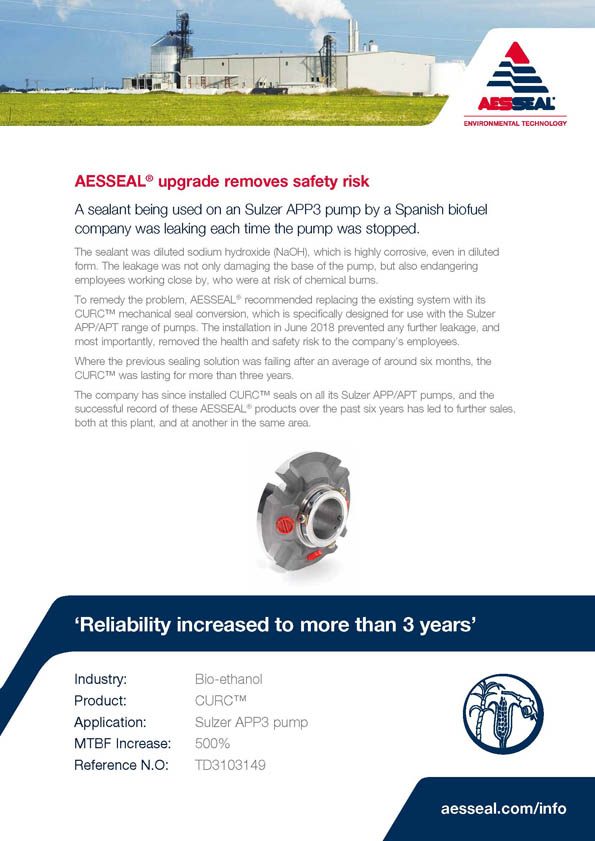

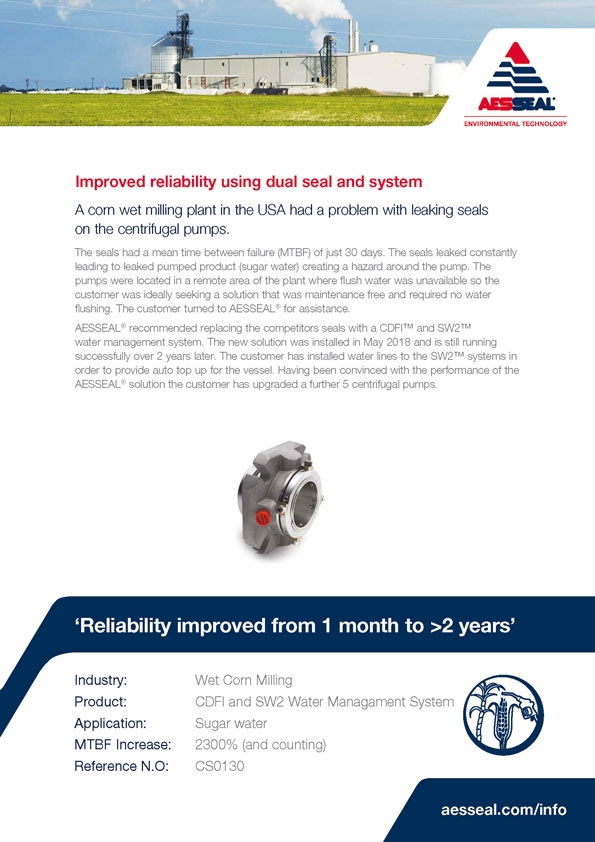

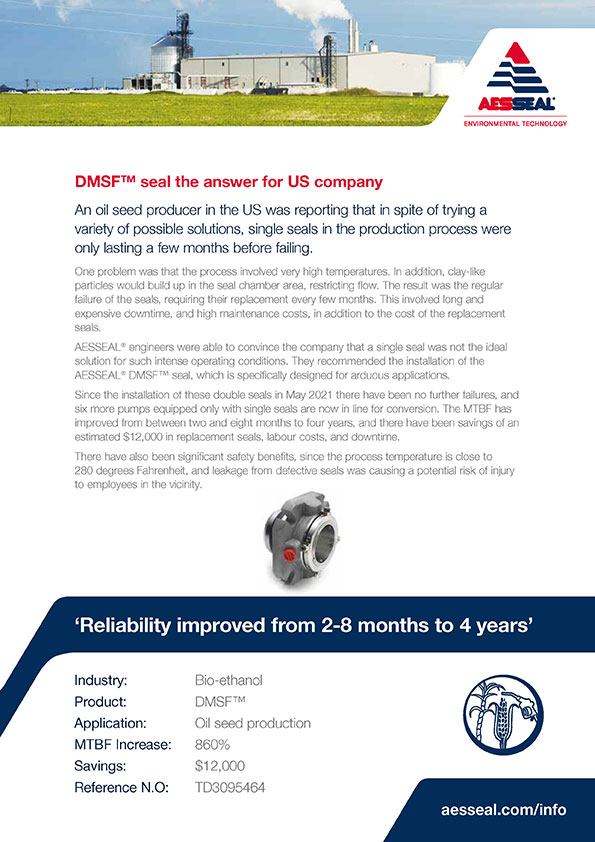

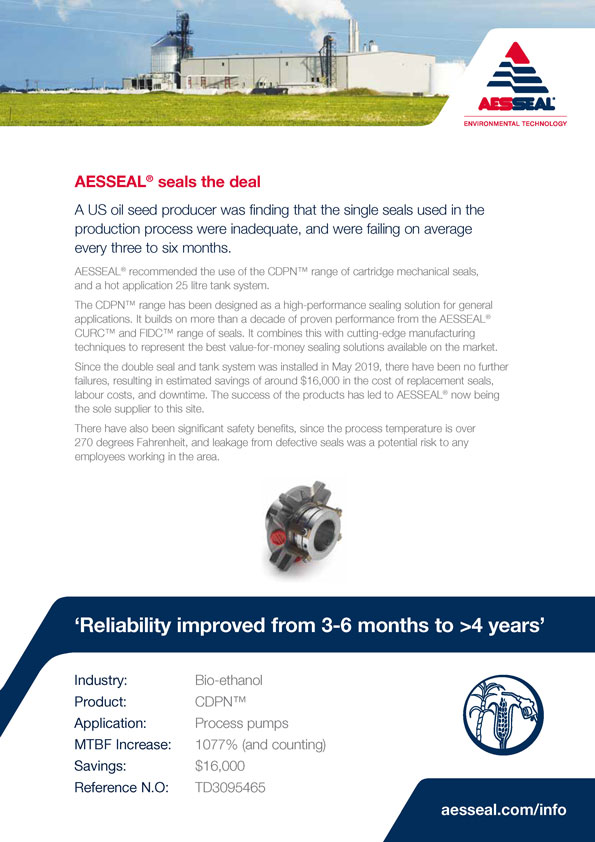

AESSEAL® offer a range of seals that are recommended for use in this industry e.g. CURC™, FIDC™, and DMSF™. The DMSF™ double mechanical seal incorporates a bi-directional pumping ring and when coupled with a seal support system such as the SP3™ can make a significant improvement to reliability (see case study REF: CH01154).

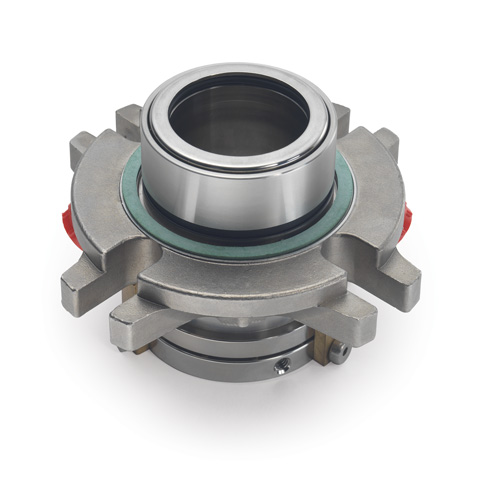

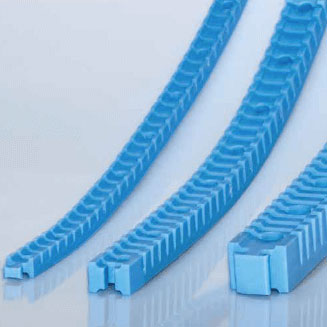

Improving the sealing of bearing housings will always have a positive impact on plant reliability. It is widely accepted that bearing failure is responsible for almost 21% of rotating equipment failure. The major cause of bearing failure is the ingress of dirt and moisture into the bearing housing. Latest generation bearing protectors prevent the ingress of dirt and moisture and are proven to reduce bearing failures. AESSEAL® bearing protection products are suitable for use in hazardous environments and provide unrivalled sealing against contaminants.

Industry Solutions

Biodiesel

Biodiesel can be blended with conventional diesel up to a level of 5% without invalidating automobile manufacturers’ warranties. Higher blend ratios are commonly found around the globe.

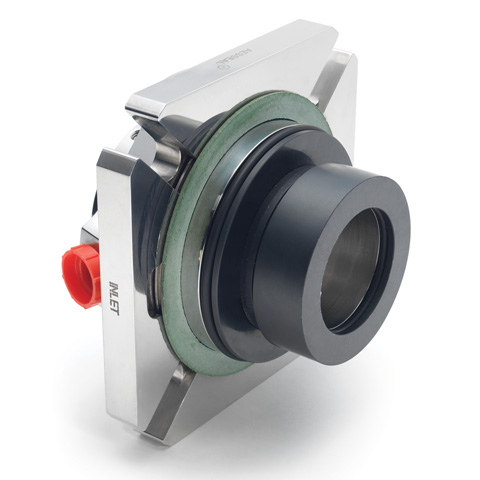

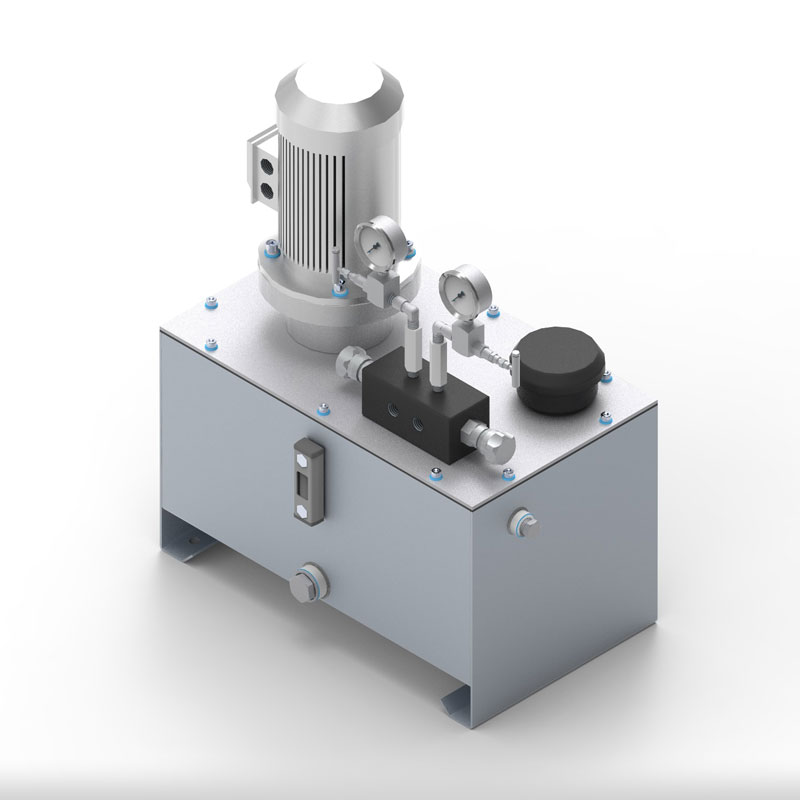

Biodiesel is produced from seed, including rape, palm, soybean and sunflower seeds. The extraction and solvent recovery process operates under vacuum at higher temperatures. With the need for conventional plan 53 systems, it is important to have turn-key instrumentation for continuous monitoring. AESSEAL® provides modular support systems, which are pre-engineered and ready to install.

Ethanol

Bioethanol can be blended with conventional gasoline by up to 5% in Europe and 15% in the USA. With very minor modifications, significantly higher blends of Bioethanol can be used and in several countries vehicles are equipped to burn these higher blends.

As demand grows, the ethanol industry is expanding the number of commodity crops used to produce bio ethanol. This variation in raw materials can present different sealing challenges. However, the need to control the fluid film and to protect bearings from contamination remains unchanged.