Recommended Products in this Industry

AESSEAL® have been helping the water and wastewater treatment industry improve reliability and uptime of their rotating equipment for many years. AESSEAL® provide sealing solutions for a wide range of pumps found in the industry, from water pumps to sludge pumps, submersible pumps and macerators, backed up by probably the best customer service in the industry.

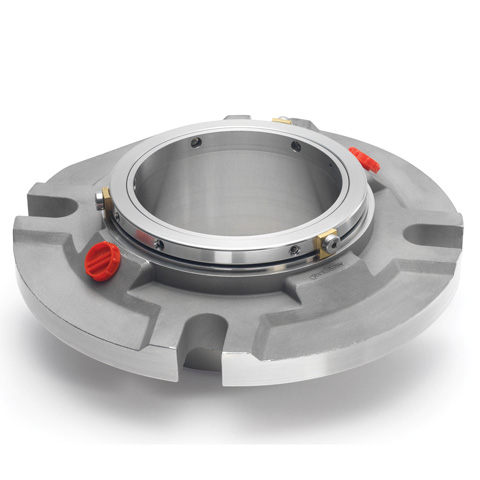

At a remote pumping station in south Australia where reliability is essential, AESSEAL® replaced the existing gland packing with a CSM seal on a high pressure booster pump. The CSM seal has been working now for 11 years saving the customer more than $41,000 (AUD).

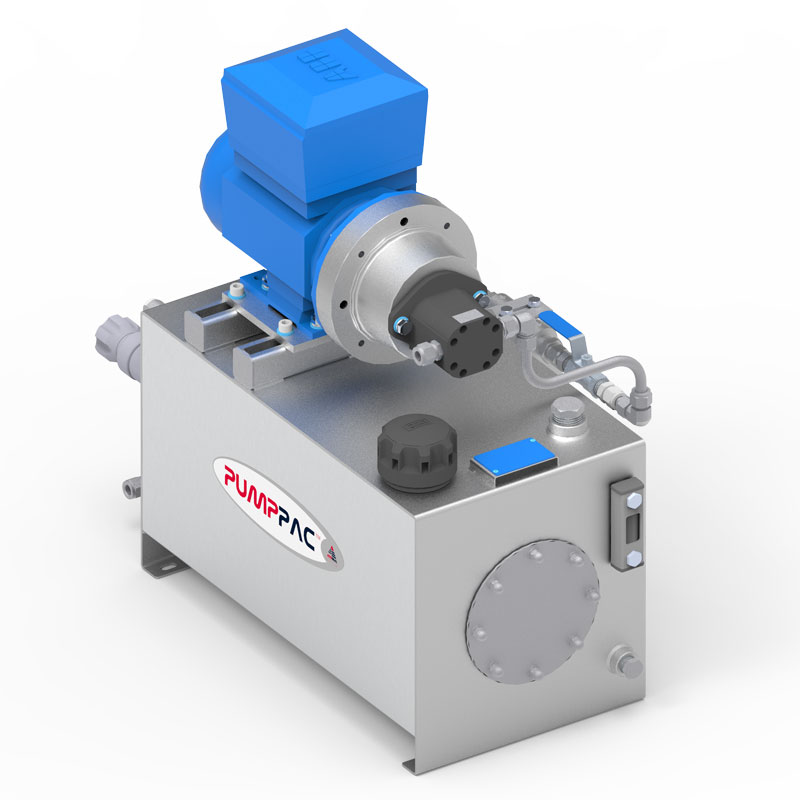

AESSEAL® water management systems in conjunction with dual seals can also reduce the amount of water consumed by your sealing systems, in one example a FIDC™ seal and SW2 water management system saves almost 900,000 gallons(US) per year compared with the customers previous sealing solution.

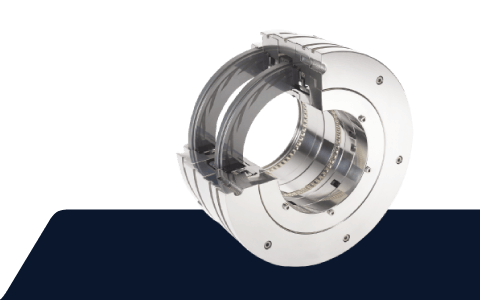

AESSEAL® also offer a range of seals (T05 Range) available with fast delivery suitable for Flygt® submersible pumps and Grindex® pumps.

Industry Solutions

Water Domestic

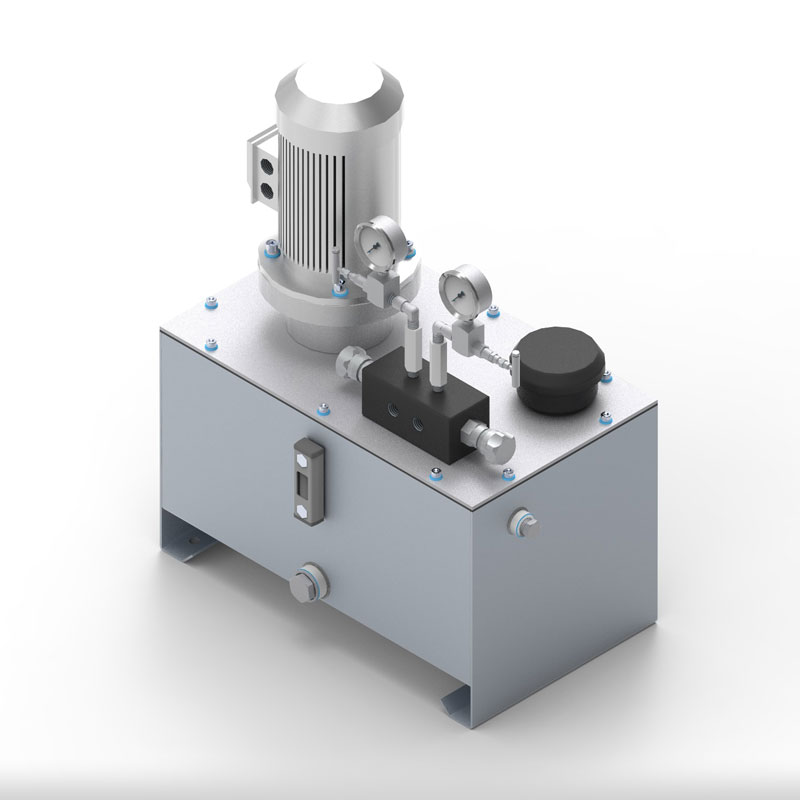

As the world faces population growth, particularly in developing countries, domestic waste processing facilities face increasing demand. Using liberal volumes of seal water flush (plan 32) is inefficient and costly.

AESSEAL® has proven technology to meet the growing global demand in this industry by eliminating costly seal flush water.

Waste Industrial

Industrial processes produce a range of different waste materials. This can often be in the form of effluent. All these materials must be processed in an environmentally conscious process either onsite or by local waste processors.

AESSEAL® has proven technology to take care of these challenges and increase equipment reliability.

Water Treatment

The removal of contaminants from waste water can take many forms. The contaminants themselves may be varied in source and concentrations, ranging from sewage and land drainage to industrial effluents.

AESSEAL® has sealing solutions to enhance uptime at each stage of the treatment process, from pumping station submersible pumps and sludge systems through to supernatant water systems. Our modular technology makes seal selection for specific pump types easy and also allows rapid delivery.