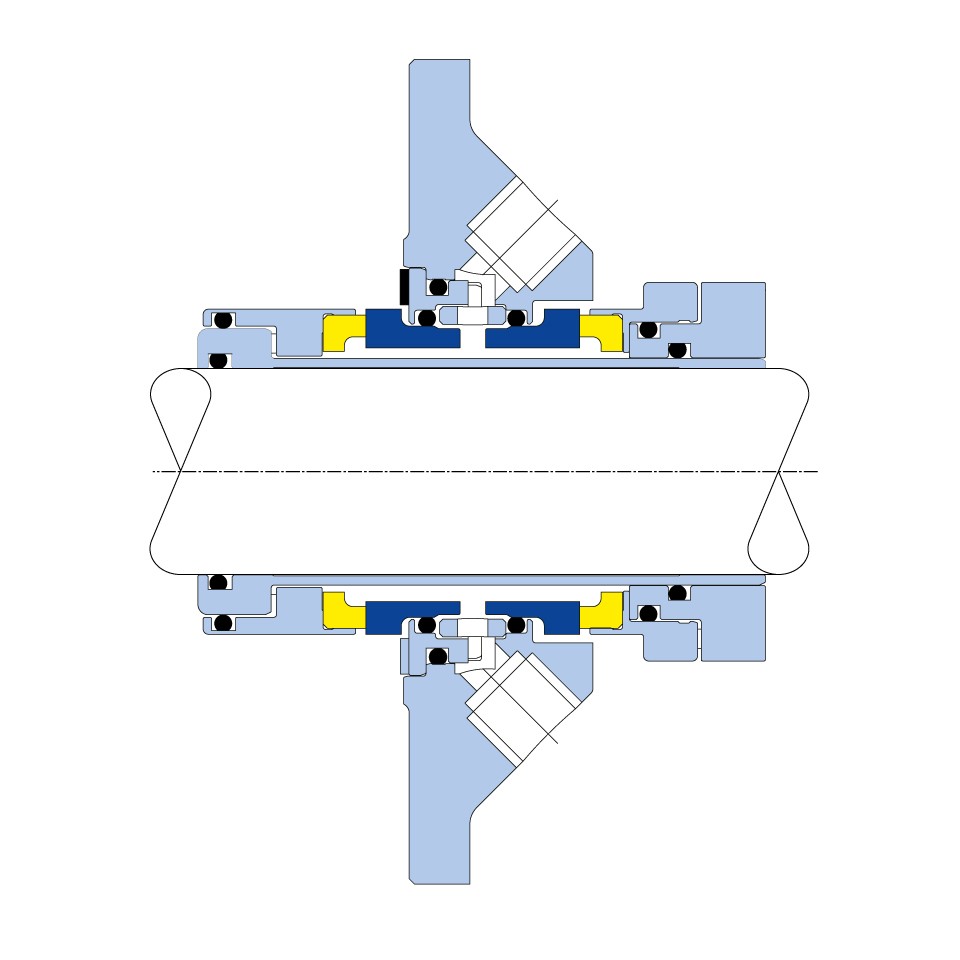

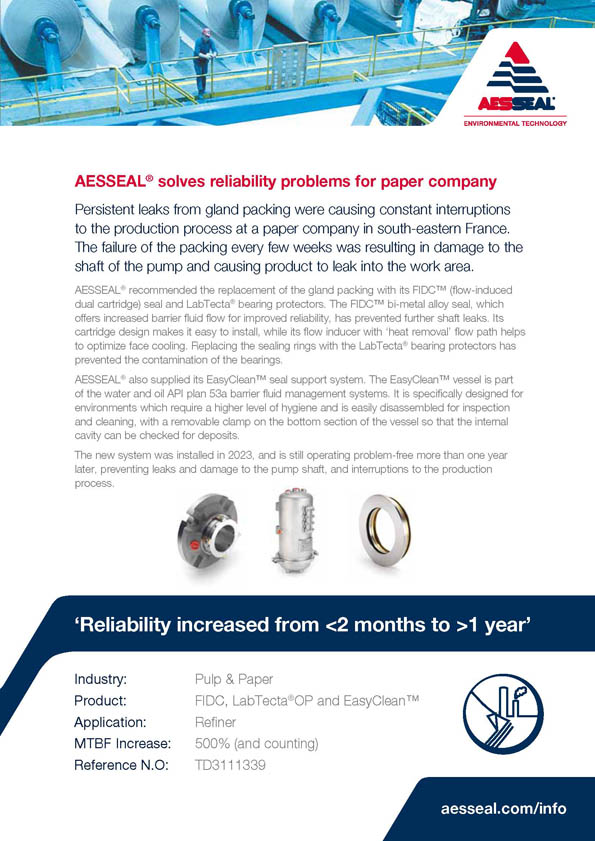

The FIDC™ seal is the next generation of high performance sealing solutions offering increased barrier fluid flow for improved reliability.

AESSEAL® has designed an innovative “bi–metal” exotic alloy seal. Alloy 20, Alloy 276, Alloy 400 and Titanium grade 2 are inventoried in popular modular wetted component sizes. Any additional commercially available special alloys are made to order. These special alloy parts are fitted to the standard Stainless Steel components. The use of a neutralizing barrier fluid protects the secondary Stainless Steel parts that are not exposed to the process fluid during normal operation.

- Flow inducer with a ‘heat removal’ flow path - helps with the removal of heat from the seal, optimizing face cooling

- Self-aligning seal faces - ensure faces remain square to shaft

- Hydraulically pressure balanced seal faces - ensures excellent sealing

- Modular design - easily adapted for different applications

- Cartridge construction - simple to install

Suitable for the following industries