The installation of an AESSEAL® DMSF™ seal at a Japanese paper plant has increased the MTBF from just six months to seven years.

More Industry Related Content

With Peter-Paul van der Meulen

The failure of a competitor’s seal at a Japanese paper plant provided an opportunity for AESSEAL to solve the problem by offering a stronger and more reliable alternative. The director and general manager of Torishima-AESSEAL Japan, Peter-Paul van der Meulen, explains how the AESSEAL DMSFTM mechanical seal helped to increase the MTBF from six months to more than seven years.

How did the contract come about?

The deal was negotiated through an agent who has a lot of experience in the pulp and paper industry. He had already worked with the company, and when their existing seal continued to fail on a regular basis, he suggested that they should talk to us.

What was the problem with the competitor’s seal?

The outboard carbon seal face was not able to handle the harsh pressure fluctuations caused by the customer’s flushing barrier water system. This pressure fluctuation was causing the carbon face to crack within six months of installation. This was resulting in frequent and costly maintenance and repeated outages, reducing the productivity of the plant.

How did AESSEAL convince the company that the DMSF seal was the right solution?

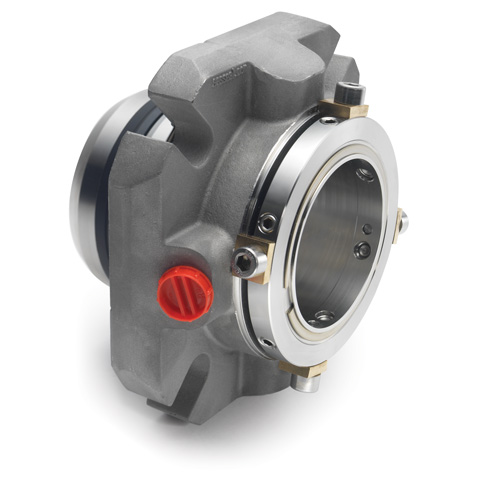

By offering harder and more durable tungsten carbide faces on the outboard seal. We were also able to demonstrate to the customer that because the DMSFTM is a tandem seal with double pressure balanced monolithic seal faces, it would be better able to withstand the severe pressure fluctuations of the barrier fluid. Its heavy-duty design, robust monolithic seal faces, machined drive lugs, and high efficiency pumping scroll is much more effective in these demanding applications.

Are you able to say what savings or other benefits have resulted from the installation of the DMSF seals?

In terms of financial savings, it is difficult to say because the seal was supplied via the agent. However, considering that the previous seal was failing every six months or so, we can safely assume that significant financial savings have been achieved in seal costs and in the cost of maintenance, downtime and loss of production.

What feedback have you had about the quality of the products or services AESSEAL has provided?

The feedback has come through the agent. He is extremely pleased and impressed with the performance of the DMSFTM seal, which has increased the MTBF to seven years, compared with the six months’ life expectancy of the seal that the company had been using previously.

Has the contract helped to win contracts with other Japanese companies?

We use this success story in all industries to demonstrate both the strength of the DMSFTM in particular, and the advantages of double seals and barrier systems in general. This has led to orders with end-users not only in the Pulp & Paper sector, but also in the Petrochemical, Steel and Chemical industries.